Research On Efficient Extraction Of Protein Isolate From Rice Grains

Exploring the efficient extraction of rice protein isolate using optimized water washing and alkali dissolution processes, highlighting significant improvements in protein yield and content.

Abstract Rice protein isolate is extracted from rice grains by water washing and alkali dissolution. Experiments show that the alkali extraction efficiency of washed rice grains is significantly improved. During the alkali extraction process, the influence of temperature is obvious. The optimized process conditions for water washing are: : Temperature 70¡ãC, solid-liquid ratio 1:6, washed 3 times; the optimized conditions for alkali extraction are: temperature 65¡ãC, alkali concentration 0.8%, time 8 h, solid-liquid ratio 1:6. Under these conditions, the product protein The content is 80.1%, and the rice protein yield is 76.2%.

Introduction to Rice Protein Isolation:

In the realm of food science and technology, the extraction and purification of protein from plant sources have garnered significant attention due to the increasing demand for sustainable and alternative protein sources. Rice, being one of the most widely consumed grains globally, presents a promising candidate for protein isolation. This post delves into a recent study focusing on the isolation of rice protein through an innovative process involving water washing and alkali dissolution, demonstrating significant improvements in extraction efficiency and protein yield.

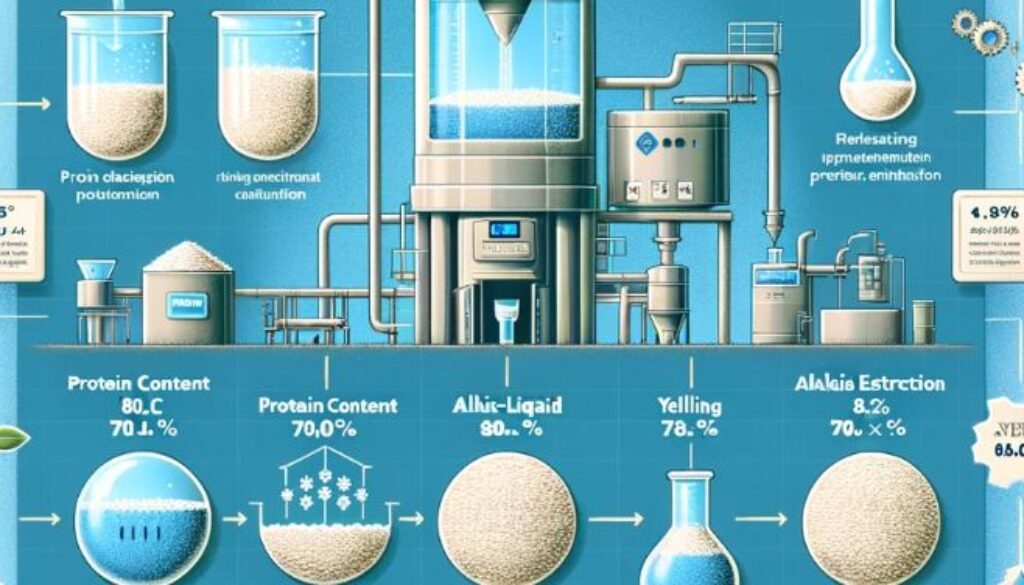

Methodology of Protein Extraction:

The methodology employed in the extraction process comprises two critical steps: water washing and alkali dissolution. The initial phase, water washing, is designed to remove impurities and prepare the rice grains for the subsequent alkali extraction. This preparation is crucial for enhancing the overall efficiency of protein isolation. The study reveals that the process conditions optimized for water washing involve a temperature of 70°C, a solid-liquid ratio of 1:6, and a procedure that is repeated three times. These conditions are meticulously selected to maximize impurity removal without compromising the integrity of the rice grains.

Optimization of Alkali Extraction Conditions:

Following the water washing phase, the alkali dissolution step is introduced. Alkali extraction has been a cornerstone in protein isolation techniques due to its effectiveness in solubilizing proteins, thereby facilitating their separation from the solid matrix. The influence of temperature during this phase is notably significant, impacting both the efficiency of protein solubilization and the quality of the final product. The optimized conditions for alkali extraction identified in the study are a temperature of 65°C, an alkali concentration of 0.8%, a duration of 8 hours, and a solid-liquid ratio of 1:6. These parameters were determined through systematic experimentation, underscoring the critical role of temperature and alkali concentration in achieving high efficiency and yield in protein extraction.

Achievements in Protein Content and Yield:

Under the optimized conditions outlined, the study reports remarkable outcomes in terms of protein content and yield. The product protein content achieved is 80.1%, while the yield of rice protein isolation stands at 76.2%. These figures are indicative of the high efficiency and effectiveness of the extraction process, offering a viable and sustainable method for producing rice protein isolate. The high protein content and yield underscore the potential of rice as a significant source of plant-based protein, suitable for various applications in the food industry and beyond.

Implications for Sustainable Protein Production:

This study not only highlights the feasibility of extracting high-quality protein from rice grains but also contributes to the broader quest for sustainable and alternative protein sources. The optimized process conditions for water washing and alkali extraction provide valuable insights for industrial applications, promising to enhance the scalability and commercial viability of rice protein production. Furthermore, the environmental and nutritional benefits of plant-based protein sources, such as rice protein isolate, underscore the importance of continued research and development in this field. By harnessing the potential of rice and other plant materials for protein extraction, we can make significant strides towards meeting the global demand for sustainable, nutritious, and accessible food sources.

For futher details of this article and research, feel free to contact our team for assistance.

About ETprotein:

ETprotein, a reputable plant protein vegan protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, oat protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, various of plant peptides etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to get a free sample of their protein products, please contact them and email sales(at)ETprotein.com today.