Research on rice residue pretreatment

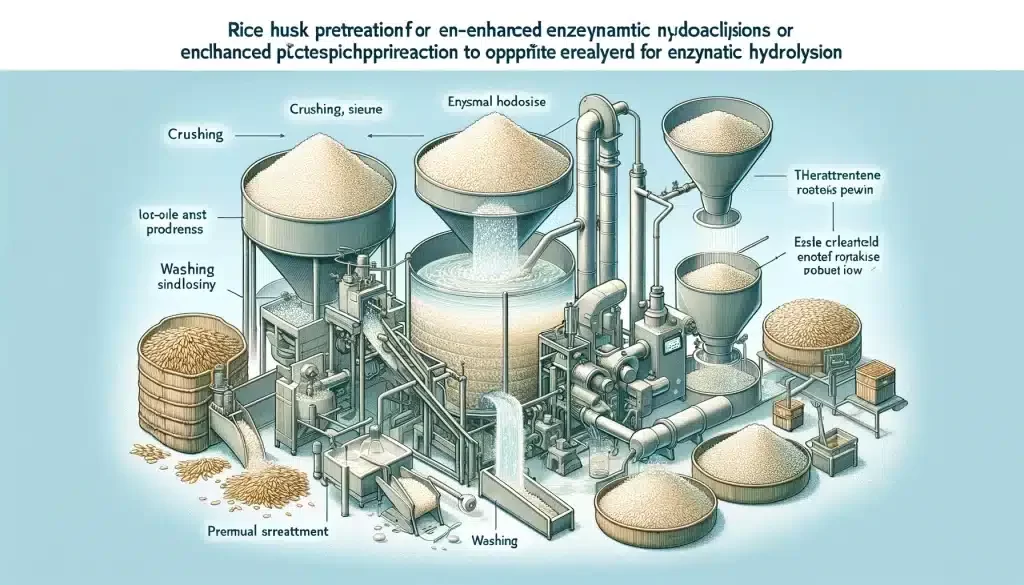

Explore efficient rice husk pretreatment methods for enhanced enzymatic hydrolysis, optimizing protein yield and purity in rice peptide production.

Keywords: rice dregs, rice peptide, enzymolysis , physicochemical property, antioxidant activity

Introduction

Rice husk, a by-product of rice milling, is abundant in protein. However, it also contains considerable amounts of fats, sugars, and microbial impurities. Prior pretreatment of rice husk can significantly reduce these impurities, enhancing the efficiency and degree of subsequent enzymatic hydrolysis for rice peptides production. Effective pretreatment strategies can minimize microbial presence and certain impurities, altering particle size distribution, which in turn, increases the surface area for protease action. This accelerates the enzymatic reaction process, simplifies subsequent operations, and elevates product purity.

Several pretreatment methods are in practice for preparing rice peptides, including crushing, washing, and thermal treatment. Crushing increases the material’s surface area, speeding up reactions and improving production efficiency. Washing aims to remove soluble components, enriching protein content. Thermal treatment modifies proteins’ tertiary structures, making them more accessible to enzymatic action. However, excessive heat may hinder hydrolysis by causing protein re-aggregation.

Materials and Methods

Materials and Reagents

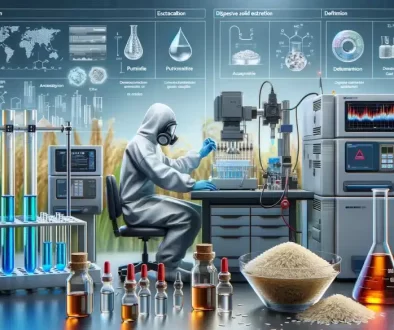

The study utilized rice husk, with reagents like copper sulfate, potassium sulfate, benzoic acid, and hydrochloric acid, all of analytical grade.

Main Instruments and Equipment

Equipment used included an LXJ-II centrifuge, an HH-SB digital thermostatic water bath, and a precision electric stirrer.

Research Methodology

The methodology involved crushing and sieving rice husk, followed by washing and thermal treatment to remove most sugars and fats. The influence of washing time, temperature, number of washes, and solid-liquid ratio on protein content and loss rate were studied.

Results and Discussion

Analysis of Major Components

The primary components of rice husk include 60.6% protein, 7.4% fat, 19.4% total sugars, 2.76% ash, and 7.8% moisture.

Effects of Washing Time on Protein Content and Loss Rate

Optimal washing conditions were identified as 60 minutes at 80°C, which yielded a protein content of 75.3% and a protein loss rate of 3.85%.

Effects of Washing Temperature on Protein Content and Loss Rate

Increasing the washing temperature showed a positive correlation with both protein content and loss rate. However, beyond 80°C, the benefits diminished, likely due to Maillard reactions. Thus, 80°C was deemed the optimal washing temperature.

Effects of Washing Number on Protein Content and Loss Rate

Two washes were found to be optimal, striking a balance between increasing protein content and minimizing protein loss.

Effects of Solid-Liquid Ratio on Protein Content and Loss Rate

A solid-liquid ratio of 7:1 was found to be most effective, offering a significant increase in protein content without excessively elevating the protein loss rate.

Verification Experiment

Combining all optimized conditions (solid-liquid ratio of 7:1, temperature at 80°C, and a washing duration of 60 minutes for two cycles), the protein content could reach 77.2% with a protein loss rate of 3.97%.

Conclusion

This study explored the pretreatment of rice husk through crushing, sieving, washing, and thermal treatment, aiming to enhance the efficiency of subsequent enzymatic hydrolysis. The optimal washing protocol was determined to significantly improve protein yield while minimizing protein loss, providing a valuable reference for future research and application in rice peptide production.

For more further detailed information of this research, feel free to contact our team for asssistance.

Original research by Xiong Weijie, Wu Weiguo(Hunan Agricultural University, Changsha 410128)

About ETprotein:

ETprotein, a reputable rice protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, etc. Our offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. We serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

Our specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Our extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample our products, please contact us and email sales(at)ETprotein.com today.