Research On The Performance Of External Circulation Airlift Reactor And Its Application In The Treatment Of Rice Distiller¡¯S Grain Waste Liquid

Exploring an airlift reactor’s efficacy in fungal cultivation and waste treatment, highlighting improved environmental and biotechnological processes through innovative reactor design.

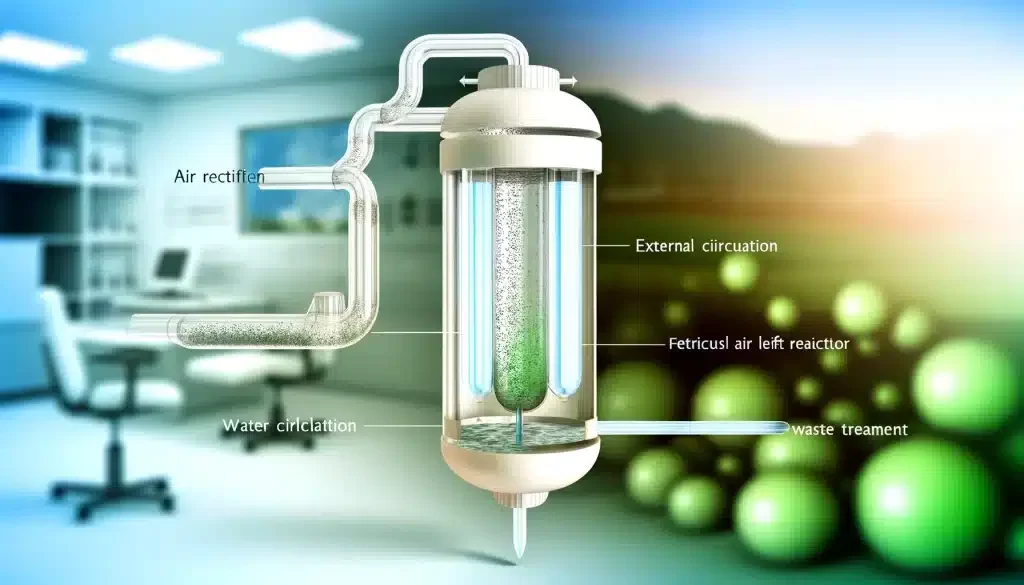

This paper studies the characteristics of the selected reactor such as gas holdup, mixing time and volumetric oxygen transfer coefficient. The experiment was conducted in the air-water system of the external circulation airlift reactor and the bubble reactor. The regression equation of the reactor was obtained through regression analysis of the experimental data obtained, and the external circulation airlift reaction with better performance was used. The BN99 fungus was cultured in the distiller’s grain waste liquid. The results are: the COD value in the waste liquid is reduced by 60-70%, the pH value rises from 5.2 to 6.5, the content of bacterial protein is as high as 38.88%, and solid and liquid are easy to separate. Therefore, in terms of fungal culture and distiller’s grain waste liquid treatment, the external circulation airlift reactor is a reactor with good performance.

Introduction to Biotechnological Reactor Optimization

In the quest to address environmental challenges and optimize industrial processes, innovative biotechnological approaches have become pivotal. Among these, the utilization of specific reactors for waste treatment and bioproduct optimization stands out. This paper delves into the exploration of an external circulation airlift reactor’s efficiency, particularly when compared to conventional bubble reactors, in fostering the cultivation of the BN99 fungus within a distiller’s grain waste liquid environment. The focal points of this study encompass gas holdup, mixing time, and volumetric oxygen transfer coefficient as primary parameters for assessing reactor performance.

Experimental Methodology and Comparative Analysis

The methodology adopted for this research entailed a comprehensive experiment conducted within an air-water system, utilizing both an external circulation airlift reactor and a bubble reactor for comparative analysis. Through rigorous regression analysis of the collected experimental data, a regression equation for the reactor was formulated, pinpointing the external circulation airlift reactor as the more efficacious option.

Superior Performance of the External Circulation Airlift Reactor

The efficacy of the external circulation airlift reactor was further underscored by its capacity to cultivate the BN99 fungus effectively within the distiller’s grain waste liquid. Remarkably, this reactor facilitated a significant reduction in the COD (Chemical Oxygen Demand) values of the waste liquid by 60-70%, while also elevating the pH value from 5.2 to 6.5. This not only indicates an enhanced degradation of organic pollutants but also showcases the reactor’s role in improving the waste liquid’s quality for subsequent processes or discharge. Moreover, the content of bacterial protein in the treated liquid reached an impressive 38.88%, underscoring the potential for nutrient recovery and the production of value-added bioproducts. Additionally, the ease of solid-liquid separation post-treatment highlights the process’s operational efficiency and the reactor’s suitability for scaling up.

Implications for Fungal Cultivation and Waste Treatment

These findings illuminate the external circulation airlift reactor’s superior performance in two critical areas: the cultivation of beneficial fungi and the treatment of distiller’s grain waste liquid. The reactor’s design, promoting efficient gas-liquid mixing and oxygen transfer, proves to be instrumental in optimizing the growth environment for the BN99 fungus, thereby enhancing bioremediation and bioproduction processes.

Concluding Remarks on Reactor Efficiency and Environmental Applications

In conclusion, the external circulation airlift reactor emerges as a robust and versatile bioreactor, offering substantial improvements over traditional bubble reactors in terms of environmental waste treatment and biotechnological applications. The reactor’s ability to drastically reduce COD values, adjust pH levels favorably, and significantly increase bacterial protein content within waste liquids, all while facilitating easy solid-liquid separation, marks a significant advancement in the field. This research not only contributes valuable insights into reactor design and operation but also underscores the potential for integrating biotechnological strategies in environmental management and sustainable industrial processes.

For futher details of this article and research, feel free to contact our team for assistance.

Original research was done by Xia Lincong, Gao Kongrong

About ETprotein:

ETprotein, a reputable plant protein vegan protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, oat protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, various of plant peptides etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to get a free sample of their protein products, please contact them and email sales(at)ETprotein.com today.