Research on the Pretreatment of Rice Feed Protein

Explore the efficient pretreatment of rice feed protein to enhance hydrolysis, improve purity, and boost industrial production efficiency in our latest study.

Keywords: rice feed protein, rice peptide, ultrafine grinding, water washing, enzymatic hydrolysis, decolorization, desalination

Introduction

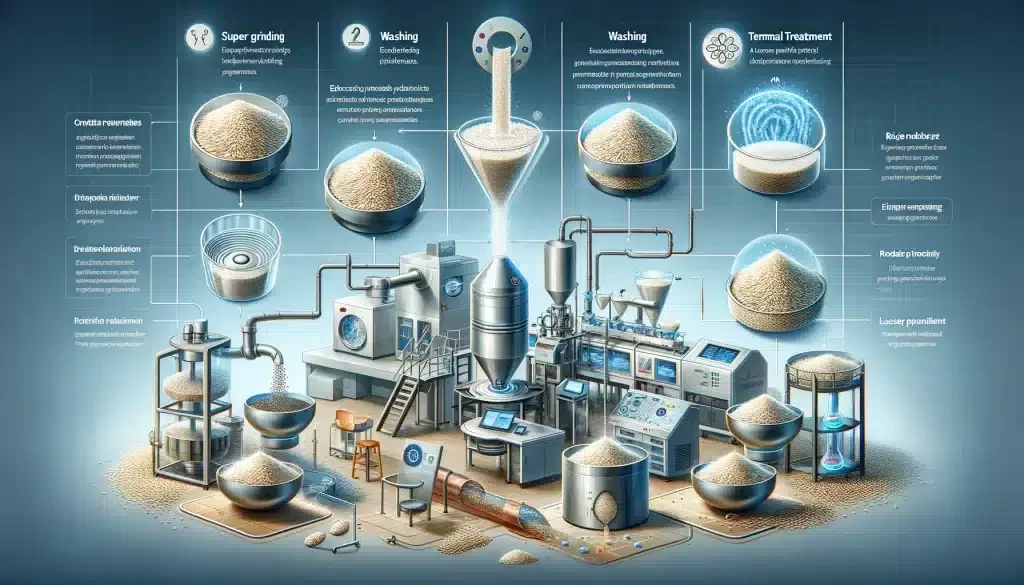

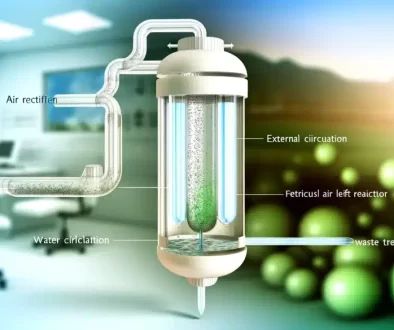

Rice feed protein, while high in protein content, also contains a relatively high amount of impurities such as sugars, fats, and microorganisms. From an experimental perspective, to improve the hydrolysis efficiency and degree of rice feed protein, and from an industrial perspective, to shorten production cycles, reduce costs, and improve production efficiency, pretreatment of rice feed protein before enzymatic hydrolysis is necessary. Pretreatment can effectively reduce impurities and microbial components in raw materials, change the particle size distribution of the materials, increase the surface area for enzyme action, accelerate enzymatic hydrolysis, speed up the entire reaction process, reduce the difficulty of subsequent operations, and improve product purity. Currently, the main methods of raw material pretreatment in the preparation of plant proteins include superfine grinding, washing, and thermal pretreatment.

Materials and Methods

Materials and Reagents

- Rice feed protein was obtained from Wuhan Jiabao Sugary Industry Co., Ltd. Main Instruments and Equipment

- A type 501 super thermostat from Shanghai Experimental Instrument Factory, a LXJ-Ⅱ type centrifuge from Shanghai Medical Analysis Instrument Factory, an LHO-300 European type super airflow pulverizer from Yixing Juneng Ultrafine Grinding Equipment Co., Ltd., and a BT-9300H laser particle size distribution instrument from Dandong Bet Instruments Co., Ltd. Experimental Method

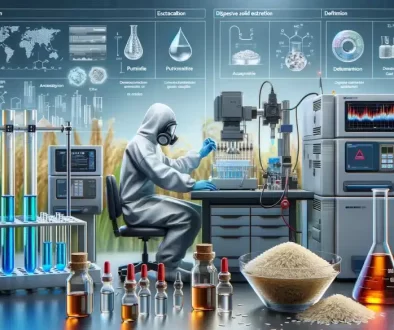

- The experiment involved superfine grinding, washing, and thermal treatment of rice feed protein. The efficiency of these methods was assessed by measuring the protein content and peptide extraction rate using micro Kjeldahl method, referring to GB5009.5-85 standards.

Results and Discussion

Superfine Grinding

- Comparison between raw materials and materials after superfine grinding showed a significant increase in protein peptide extraction rate, from 42.1% to 59.4%, highlighting the necessity of superfine grinding before enzymatic hydrolysis. Influence of Grinding Time and Electrical Frequency on Superfine Grinding

- Adjusting grinding times and electrical frequencies showed variations in particle size distribution and protein peptide extraction rates, with optimal conditions found at a grinding time of 30 minutes and an electrical frequency of 80 Hz, achieving an extraction rate of 68.3%, about 20% higher than that of the raw material. Washing

- The effects of washing time, temperature, number of washes, and liquid-solid ratio on protein content and loss rate were explored, with optimal washing conditions determined to be a liquid-solid ratio of 7:1, temperature of 60°C, and a washing time of 60 minutes twice. This achieved a protein content of 85.86% and a protein loss rate of 3.67%.

Conclusion

This study investigated the impact of pretreatment on the substrate itself and the enzymatic hydrolysis of rice feed protein, determining the final pretreatment conditions. Superfine grinding, as a new technology, was emphasized for its efficiency in improving enzymatic hydrolysis levels. Optimal conditions for washing were also established, significantly improving protein content. The study underlines the importance of pretreatment in enhancing the efficiency of rice feed protein hydrolysis, paving the way for industrial application advancements.

For more further detailed information of this research, feel free to contact our team for asssistance.

The original research is done by HE Qiangfei,GUO Guanxin,YU Qiusheng(School of Food Science, Jiangnan University, Wuxi,214122, China) The ariticle ID is: doi: 10.7666/d.y1397665