Robotics Handling Hindrances in Food Processing Industry.

-

Table of Contents

- Robotics Overcoming Challenges in the Food Processing Industry

- Introduction to Robotics in Food Processing

- Labor Shortages and Robotics as a Solution

- Hygiene and Safety Standards

- Cost and Complexity of Robotic Systems

- Customization and Flexibility Issues

- Integration with Existing Infrastructure

- Regulatory Compliance and Robotics

- Conclusion: Embracing Robotics for a Better Future

- ETprotein: Enhancing Food Processing with High-Quality Protein Products

Robotics Overcoming Challenges in the Food Processing Industry

The food processing industry is a critical component of the global economy, providing consumers with a wide range of products that are essential for daily sustenance. However, the industry faces numerous challenges, ranging from labor shortages to stringent hygiene standards. Robotics has emerged as a transformative solution, offering innovative ways to address these hindrances. This article delves into the various obstacles faced by the food processing sector and how robotics is paving the way for a more efficient and sustainable future.

Introduction to Robotics in Food Processing

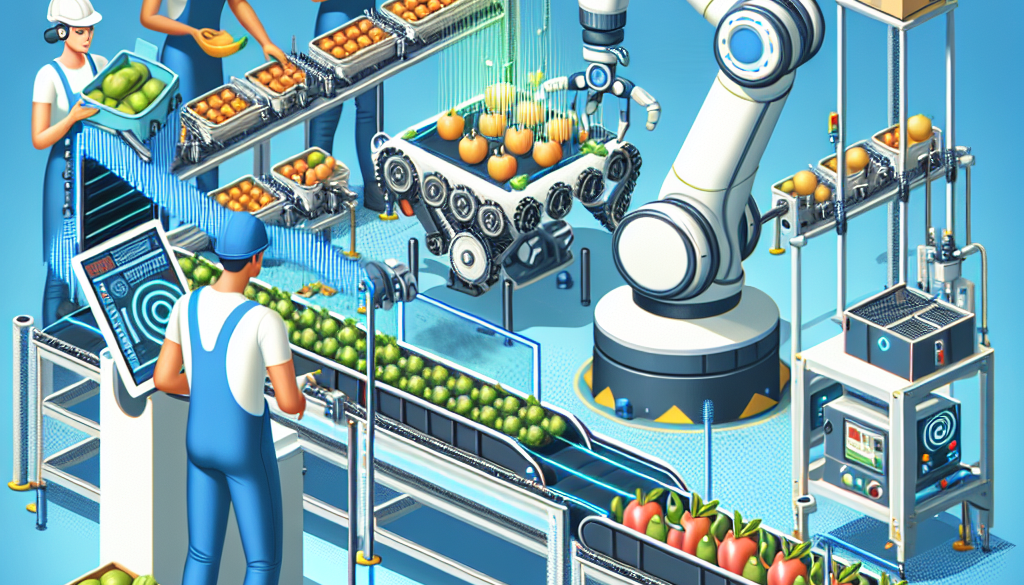

Robotics technology has been steadily making its way into the food processing industry, driven by the need for precision, speed, and consistency. The integration of robots in various stages of food production, from sorting and packaging to cooking and assembly, is revolutionizing the way food is processed and distributed. Despite the potential benefits, the adoption of robotics is not without its challenges.

Labor Shortages and Robotics as a Solution

Labor shortages have long plagued the food processing industry. The work is often repetitive, physically demanding, and takes place in environments that can be less than desirable. Robotics offers a solution to this problem by taking on tasks that are difficult to staff, thereby reducing the reliance on human labor and increasing productivity.

- Automated systems can operate around the clock, increasing output and efficiency.

- Robots can perform tasks with precision and consistency, improving product quality.

- By handling dangerous or monotonous jobs, robots can reduce workplace injuries and improve employee satisfaction in more skilled positions.

Hygiene and Safety Standards

Food safety is paramount in the processing industry, with strict regulations governing every aspect of production. Robotics can help maintain high hygiene standards by minimizing human contact with food products.

- Robots can be designed to withstand rigorous cleaning protocols, reducing the risk of contamination.

- Automated systems can monitor and maintain optimal conditions for food safety, such as temperature and humidity levels.

- With advanced sensors, robots can detect and remove defective or contaminated products from the production line.

Cost and Complexity of Robotic Systems

While robotics offers many advantages, the initial cost and complexity of these systems can be a significant barrier for many food processors, particularly small to medium-sized enterprises (SMEs).

- The high capital investment required for robotic technology can deter companies from adopting these systems.

- There is a need for skilled personnel to operate and maintain robotic equipment, which can add to operational costs.

- Integrating robotics into existing production lines often requires significant modifications, further increasing expenses.

Customization and Flexibility Issues

Food products come in various shapes, sizes, and consistencies, which can pose a challenge for robotic systems that require precise programming and setup.

- Robots need to be highly adaptable to handle the vast range of products in the food industry.

- Developing flexible robotic systems that can quickly switch between tasks is essential for processors handling multiple product lines.

- Advancements in machine learning and artificial intelligence are helping to create more adaptable robots that can learn and adjust to new tasks with minimal human intervention.

Integration with Existing Infrastructure

Another significant challenge is integrating robotic systems with existing infrastructure and workflows without causing disruptions.

- Many food processing facilities are not designed with robotics in mind, requiring substantial retrofitting or even new construction.

- Ensuring seamless communication between robotic systems and legacy equipment is crucial for efficient operations.

- Collaborative robots, or cobots, are being developed to work alongside human workers, offering a more flexible and less disruptive integration option.

Regulatory Compliance and Robotics

The food processing industry is heavily regulated to ensure consumer safety. Robotics must comply with these regulations, which can vary widely from one region to another.

- Robotic systems must meet food-grade material requirements and be capable of withstanding the harsh cleaning chemicals used in food processing plants.

- Manufacturers of robotic systems must stay abreast of changing regulations to ensure their products remain compliant.

- There is a growing need for standardization in robotic systems to facilitate easier compliance with international food safety standards.

Conclusion: Embracing Robotics for a Better Future

In conclusion, while the food processing industry faces significant challenges in adopting robotics, the potential benefits are too great to ignore. Robotics offers solutions to labor shortages, helps maintain hygiene and safety standards, and can increase efficiency and productivity. Overcoming the hurdles of cost, complexity, customization, integration, and regulatory compliance will require concerted efforts from technology developers, food processors, and regulatory bodies. As the industry continues to innovate, robotics will undoubtedly play a pivotal role in shaping the future of food processing.

ETprotein: Enhancing Food Processing with High-Quality Protein Products

In addition to robotics, the use of high-quality ingredients is essential in the food processing industry. ETprotein is a company that specializes in providing top-tier protein products that can enhance the nutritional value and quality of food products. Their range of organic and non-GMO proteins, including rice, pea, and seed-based proteins, are ideal for various applications in the food and beverage sector. With a commitment to quality and customer satisfaction, ETprotein is an excellent partner for businesses looking to improve their offerings with superior protein ingredients.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.