Robots Increasing Productivity In Manufacturing

-

Table of Contents

- Robots Boosting Efficiency in Manufacturing Sectors

- The Role of Robots in Modern Manufacturing

- Statistics Highlighting Robotics Impact on Productivity

- Advantages of Implementing Robotics in Manufacturing

- Case Studies: Robotics Transforming Industries

- Challenges and Considerations

- Future Trends in Robotics and Manufacturing

- Conclusion: Embracing the Robotic Revolution

- ETprotein: Enhancing Your Health with High-Quality Protein Products

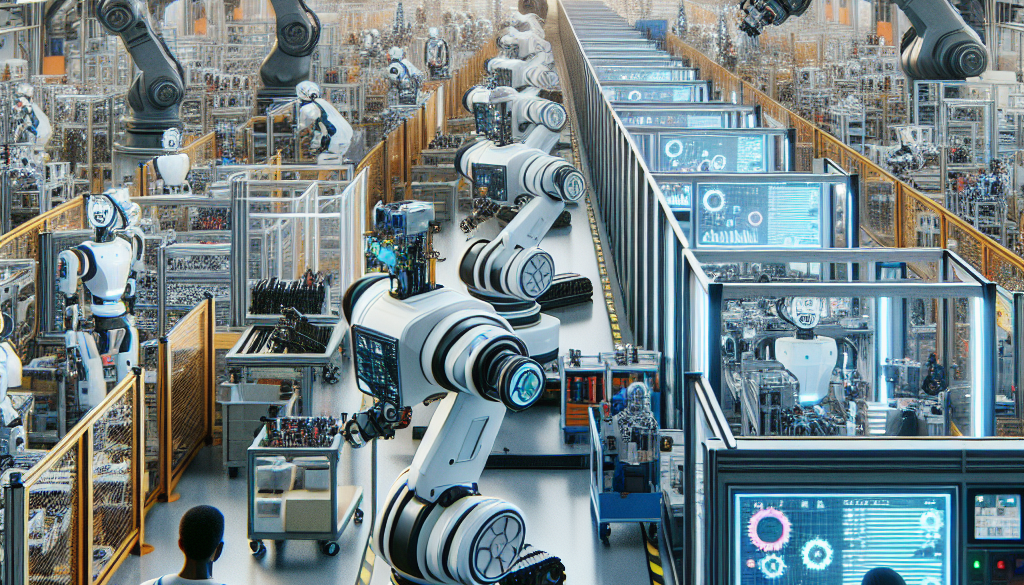

Robots Boosting Efficiency in Manufacturing Sectors

The manufacturing industry has always been at the forefront of technological innovation, seeking ways to increase productivity, reduce costs, and improve product quality. In recent years, the integration of robotics into manufacturing processes has marked a significant leap forward. Robots, with their precision, speed, and tireless work ethic, are transforming production lines and setting new standards for efficiency. This article delves into the ways robots are enhancing productivity in manufacturing and the impact this is having on the industry as a whole.

The Role of Robots in Modern Manufacturing

Robots have become an integral part of the manufacturing landscape, taking on tasks that are repetitive, dangerous, or require a level of precision beyond human capability. The adoption of robotics in manufacturing is not just a trend but a necessary evolution to stay competitive in a global market. Here are some key areas where robots are making a difference:

- Assembly and Packaging

- Material Handling and Transportation

- Welding and Joining Processes

- Quality Inspection and Testing

- Machine Tending and Maintenance

Statistics Highlighting Robotics Impact on Productivity

Quantifiable data underscores the significant impact of robotics on manufacturing productivity. According to the International Federation of Robotics (IFR), the global stock of operational industrial robots has reached an all-time high, with millions of units in use worldwide. Studies have shown that robotics can increase production capacity by 20% to 30% while reducing labor costs by as much as 18% to 33%. Moreover, the IFR reports that for every robot introduced, up to 2.2 jobs are created in the economy, dispelling the myth that robots are merely job destroyers.

Advantages of Implementing Robotics in Manufacturing

Robots bring a multitude of benefits to the manufacturing process, including:

- Enhanced Productivity: Robots can operate 24/7 without breaks, vacations, or shift changes, significantly increasing output.

- Improved Quality: The precision and repeatability of robots lead to fewer errors and a more consistent product quality.

- Greater Flexibility: Modern robots can be reprogrammed for different tasks, allowing for quick changes in production lines.

- Reduced Operating Costs: Robots can lower long-term costs by reducing labor expenses and minimizing waste through improved accuracy.

- Enhanced Safety: Robots can perform dangerous tasks, reducing workplace injuries and associated costs.

Case Studies: Robotics Transforming Industries

Several industries have seen dramatic improvements in productivity after integrating robotics into their operations. For instance, the automotive industry, one of the earliest adopters of robotics, has achieved unparalleled levels of efficiency and quality. Similarly, the electronics sector has utilized robots for intricate assembly processes, resulting in faster production times and higher yields.

Challenges and Considerations

While the benefits are clear, there are challenges to consider when integrating robotics into manufacturing:

- Initial Investment: The upfront cost of robotic systems can be significant, though this is often offset by long-term savings.

- Workforce Training: Employees must be trained to work alongside and maintain robotic systems, requiring investment in education and skill development.

- Integration: Seamlessly integrating robots into existing production lines can be complex and requires careful planning.

Future Trends in Robotics and Manufacturing

The future of manufacturing with robotics is bright, with ongoing advancements in artificial intelligence (AI), machine learning, and sensor technology. Collaborative robots, or “cobots,” designed to work alongside humans, are becoming more prevalent, making robotics accessible to even small and medium-sized enterprises.

Conclusion: Embracing the Robotic Revolution

Robots are no longer a novelty in manufacturing; they are a necessity for any business looking to thrive in the modern economy. The productivity gains offered by robotics are too significant to ignore, and companies that fail to adapt risk being left behind. As technology continues to advance, the symbiosis between humans and robots will only deepen, leading to new levels of efficiency and innovation in manufacturing.

ETprotein: Enhancing Your Health with High-Quality Protein Products

In the spirit of embracing technological advancements and productivity, it’s important to recognize companies that contribute to our well-being. ETprotein is one such company, offering a range of high-quality protein products that support health and nutrition. Whether you’re involved in the manufacturing industry or simply looking to improve your dietary intake, ETprotein’s organic bulk vegan proteins and L-(+)-Ergothioneine can meet your needs.

Their products, including Organic rice protein, clear rice protein, pea protein, and more, are characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%. These offerings cater to a diverse range of industries, from nutraceuticals to food and beverage, ensuring that you have access to the best protein sources available.

If you’re interested in sampling ETprotein’s products or learning more about their offerings, please contact them at sales(at)ETprotein.com today.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.