Role of Automation in the Food Sector

-

Table of Contents

- Automation Revolutionizing the Food Sector: Efficiency and Innovation

- The Emergence of Automation in Food Production

- Enhancing Food Processing with Automation

- Automation in Food Service and Delivery

- Impact of Automation on Food Safety and Traceability

- Statistical Insights into Automation in the Food Sector

- Challenges and Considerations

- Conclusion: The Future of Food is Automated

- ETprotein: Your Partner for High-Quality Protein Products

Automation Revolutionizing the Food Sector: Efficiency and Innovation

The food sector has always been a cornerstone of human civilization, providing sustenance and comfort. However, as the world’s population continues to grow and resources become more strained, the industry has had to evolve. One of the most significant changes in recent years has been the introduction and expansion of automation. This technological advancement is transforming the food sector, from production to packaging and distribution. In this article, we will explore the multifaceted role of automation in the food industry and how it is shaping the future of food production and consumption.

The Emergence of Automation in Food Production

Automation in food production is not a new concept, but its application has become more widespread and sophisticated. The use of machines to plant, harvest, process, and package food has led to a significant increase in efficiency and a decrease in labor costs. For instance, automated planting systems can now sow seeds at the perfect depth and spacing, while drones monitor crop health from above, providing precise data for farmers to act upon.

Enhancing Food Processing with Automation

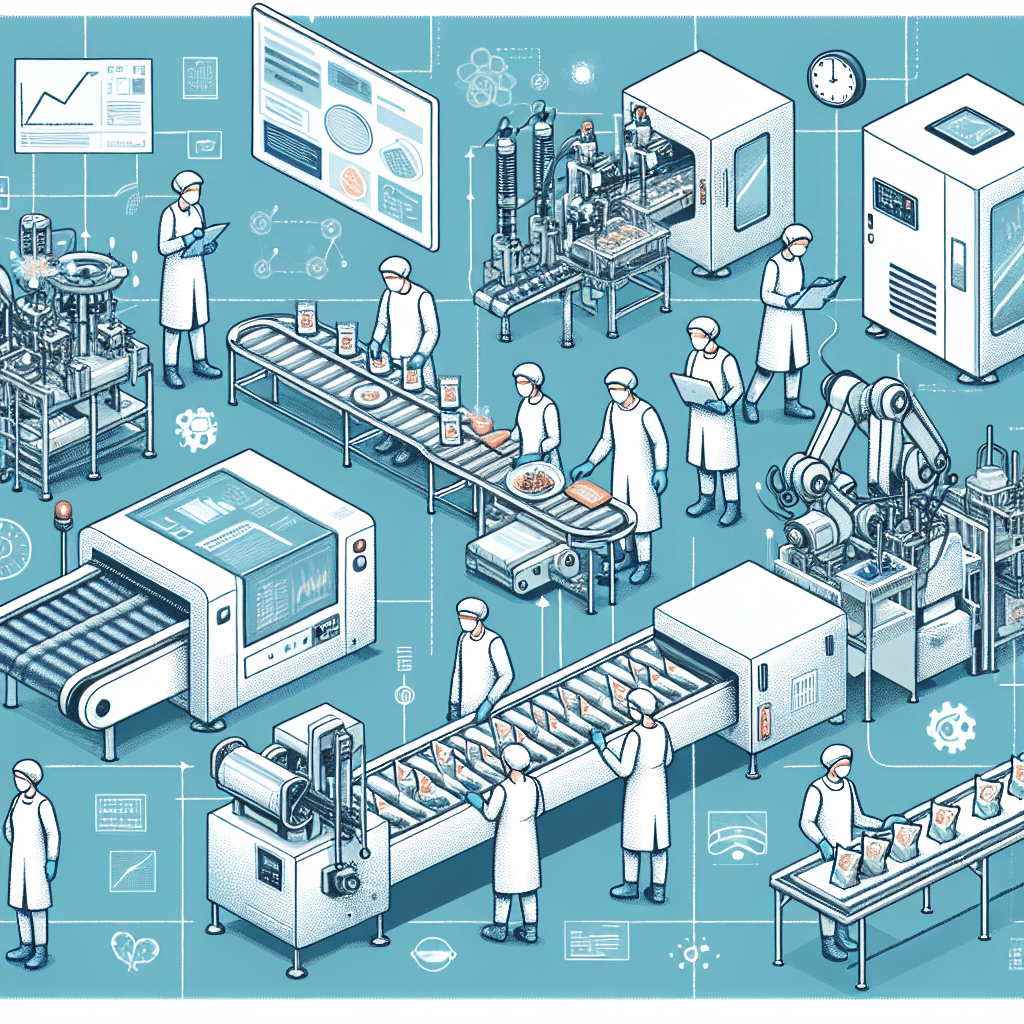

Food processing has seen a remarkable transformation with the advent of automation. Machines can now handle tasks such as sorting, cutting, and packaging with speed and precision that far surpass human capabilities. This not only improves the consistency and quality of food products but also minimizes waste and contamination risks.

- Automated Sorting Systems: These systems use cameras and sensors to sort food items by size, color, and quality, ensuring only the best products make it to the market.

- Robotic Packaging Lines: These lines can package food at a rapid pace, with the ability to adjust to different sizes and shapes, reducing downtime and material waste.

Automation in Food Service and Delivery

The food service industry is also experiencing a shift with the integration of automation. Fast-food chains and restaurants are beginning to use automated systems to take orders, prepare food, and even serve customers. Additionally, the rise of food delivery services has led to the development of automated delivery vehicles and drones, aiming to reduce delivery times and costs.

- Self-service Kiosks: These kiosks allow customers to place their orders without human interaction, streamlining the ordering process and reducing wait times.

- Automated Cooking Appliances: Devices like automated grills and fryers can cook food consistently and safely, freeing up staff to focus on customer service.

Impact of Automation on Food Safety and Traceability

Food safety is a paramount concern in the food sector, and automation has played a pivotal role in enhancing traceability and safety protocols. Automated tracking systems can monitor the journey of food products from farm to table, providing valuable data that can be used to quickly trace and address any contamination issues.

- RFID Technology: Radio-frequency identification tags on food products allow for real-time tracking throughout the supply chain.

- Automated Inspection Systems: These systems use advanced imaging technology to detect foreign objects or quality defects in food products.

Statistical Insights into Automation in the Food Sector

Statistics highlight the growing influence of automation in the food industry. According to a report by the Association for Packaging and Processing Technologies, 94% of food packaging operations are expected to be automated within the next decade. Moreover, the global food automation market is projected to reach $29.4 billion by 2027, growing at a CAGR of 9.5% from 2020 to 2027, as per a study by Meticulous Research.

Challenges and Considerations

Despite the benefits, automation also presents challenges. The initial cost of implementing automated systems can be high, and there is the ongoing issue of job displacement for workers. Additionally, the reliance on technology raises concerns about cybersecurity and the potential for system failures.

- Cost of Implementation: High upfront costs can be a barrier for small to medium-sized enterprises.

- Workforce Transition: As automation takes over repetitive tasks, there is a need for retraining and upskilling workers for more complex roles.

Conclusion: The Future of Food is Automated

In conclusion, automation is playing a crucial role in the food sector, driving efficiency, innovation, and safety. While there are challenges to be addressed, the benefits of automation in terms of productivity, quality, and sustainability are undeniable. As technology continues to advance, we can expect to see even more sophisticated applications of automation in the food industry, shaping the way we produce, process, and consume food for years to come.

ETprotein: Your Partner for High-Quality Protein Products

In line with the advancements in the food sector, ETprotein is at the forefront of providing high-quality protein products that cater to the needs of a modern, health-conscious consumer. Their extensive range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) products are perfect for food manufacturers looking to incorporate nutritious and sustainable ingredients into their offerings. With a commitment to non-GMO and allergen-free attributes, ETprotein ensures that their products meet the highest standards of quality and taste.

Whether you are in the business of sports nutrition, dietary supplements, or developing innovative food and beverage products, ETprotein’s expertise and product range can help you stay ahead in a competitive market. To explore how ETprotein’s protein solutions can enhance your product line, contact them at sales(at)ETprotein.com today.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.