Role of the Incorporation of Machine Vision to Improve Food Inspections

-

Table of Contents

- Enhancing Food Safety: The Role of Machine Vision in Food Inspections

- The Importance of Food Inspections

- What is Machine Vision?

- Statistics Supporting Machine Vision Adoption

- Applications of Machine Vision in Food Inspections

- Benefits of Machine Vision in Food Inspections

- Challenges and Considerations

- Conclusion: The Future of Food Inspections with Machine Vision

- ETprotein: Commitment to Quality and Safety

Enhancing Food Safety: The Role of Machine Vision in Food Inspections

The safety and quality of food are paramount concerns for consumers, producers, and regulators alike. With the global food supply chain becoming increasingly complex, ensuring that food products meet stringent safety standards is more challenging than ever. One of the most promising solutions to this challenge is the incorporation of machine vision technology into food inspections. This article explores how machine vision is revolutionizing the food industry by enhancing the accuracy, efficiency, and reliability of food safety inspections.

The Importance of Food Inspections

Food inspections are critical for detecting contaminants, ensuring compliance with regulations, and preventing foodborne illnesses. Traditional inspection methods often rely on human visual assessment, which can be subjective and prone to error. The integration of machine vision offers a more objective and consistent approach to food inspections, leading to safer food products for consumers.

What is Machine Vision?

Machine vision refers to the use of cameras, software, and computer algorithms to simulate human vision in industrial applications. It involves capturing images of products and analyzing them to detect defects, contaminants, or deviations from established standards. Machine vision systems can operate at high speeds and with a level of precision that far exceeds human capabilities.

Statistics Supporting Machine Vision Adoption

- According to a report by MarketsandMarkets, the global machine vision market size is projected to reach USD 14.7 billion by 2025, growing at a CAGR of 6.1% from 2020 to 2025.

- A study by the Association for Packaging and Processing Technologies (PMMI) indicates that food manufacturers are increasingly adopting machine vision to comply with food safety regulations.

- Research by the Food and Agriculture Organization (FAO) suggests that foodborne diseases affect approximately 600 million people annually, highlighting the need for improved inspection methods.

Applications of Machine Vision in Food Inspections

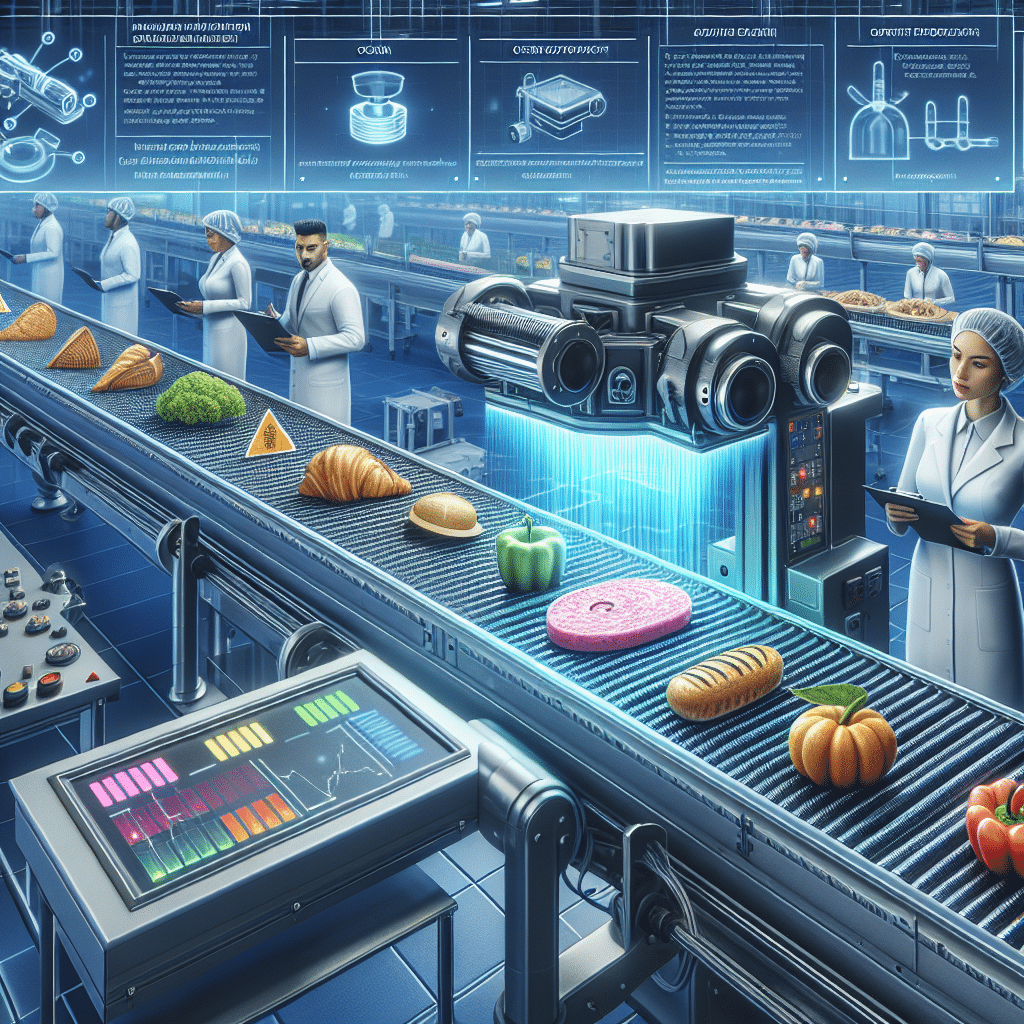

Machine vision systems are versatile and can be applied to various stages of food production and packaging. Here are some key applications:

- Sorting and Grading: Machine vision can sort food products based on size, color, shape, and ripeness, ensuring that only high-quality items reach consumers.

- Contaminant Detection: Advanced imaging techniques can identify foreign objects or substances that are invisible to the naked eye, reducing the risk of contamination.

- Label Verification: Machine vision ensures that packaging and labeling are accurate, which is crucial for allergen management and regulatory compliance.

- Seal Integrity: Inspection systems can check the integrity of seals on food packaging, preventing leaks and spoilage.

Benefits of Machine Vision in Food Inspections

The incorporation of machine vision into food inspections offers numerous benefits:

- Enhanced Accuracy: Machine vision systems provide precise and consistent inspections, reducing the likelihood of human error.

- Increased Efficiency: These systems can process large volumes of food products at high speeds, improving throughput and productivity.

- Cost Savings: By automating inspections, machine vision reduces labor costs and minimizes the risk of costly recalls due to safety issues.

- Improved Traceability: Digital records generated by machine vision systems facilitate traceability throughout the supply chain, aiding in recall management and quality control.

Challenges and Considerations

While machine vision offers significant advantages, there are challenges to its implementation:

- Initial Investment: The cost of setting up machine vision systems can be high, although the return on investment can be quickly realized through improved efficiency and reduced waste.

- Technical Complexity: Developing and maintaining machine vision systems requires specialized knowledge and expertise.

- Regulatory Compliance: Machine vision systems must be designed to comply with food safety regulations, which can vary by region and product type.

Conclusion: The Future of Food Inspections with Machine Vision

The incorporation of machine vision into food inspections is a game-changer for the food industry. By offering unparalleled accuracy, efficiency, and reliability, machine vision systems are setting new standards for food safety. As technology continues to advance, we can expect even more sophisticated applications of machine vision that will further enhance the quality and safety of our food supply.

For companies like ETprotein, which are committed to providing high-quality protein products, the adoption of machine vision technology in their production and inspection processes could ensure the highest standards of safety and quality for their customers.

ETprotein: Commitment to Quality and Safety

ETprotein is a company that could benefit from the integration of machine vision in their production lines. By ensuring that their organic bulk vegan proteins and L-(+)-Ergothioneine products meet the highest safety standards, ETprotein can continue to serve their customers with confidence. The use of machine vision could help in maintaining the purity and quality of their products, which is essential for their diverse range of industries, including nutraceuticals, pharmaceuticals, and food and beverage.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.