Seven Principles That Define HACCP

-

Table of Contents

- HACCP Principles: Ensuring Food Safety and Quality

- Principle 1: Conduct a Hazard Analysis

- Principle 2: Determine the Critical Control Points (CCPs)

- Principle 3: Establish Critical Limits

- Principle 4: Establish Monitoring Procedures

- Principle 5: Establish Corrective Actions

- Principle 6: Establish Verification Procedures

- Principle 7: Establish Record-Keeping and Documentation Procedures

- Conclusion: The Importance of HACCP in Food Safety

- Choose ETprotein for Your Protein Needs

HACCP Principles: Ensuring Food Safety and Quality

Food safety is a critical concern for consumers, businesses, and regulatory agencies worldwide. The Hazard Analysis and Critical Control Points (HACCP) system is a scientific approach designed to prevent food safety hazards from compromising the quality and safety of food products. This article delves into the seven core principles that define HACCP, providing valuable insights into how this system can be effectively implemented to ensure food safety.

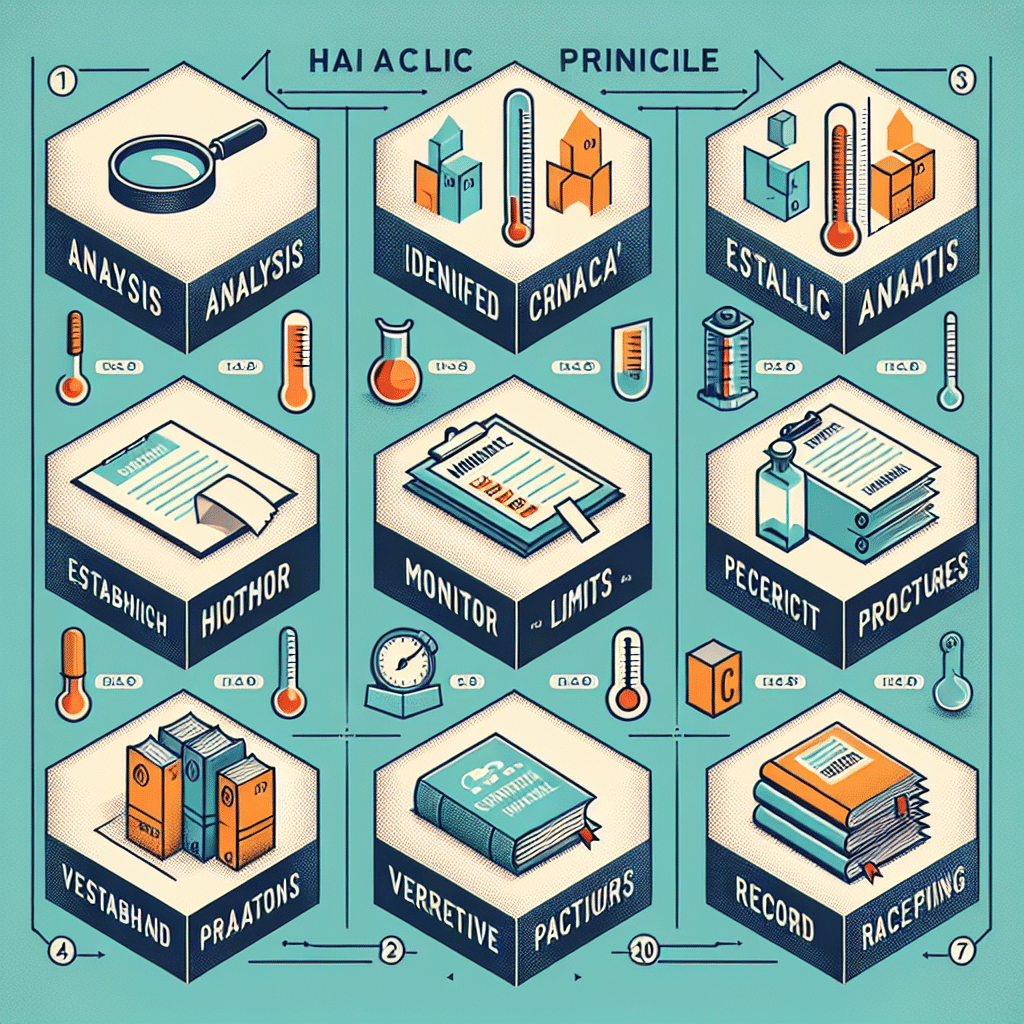

Principle 1: Conduct a Hazard Analysis

The first step in the HACCP system is to conduct a thorough hazard analysis. This involves identifying potential hazards that could affect food safety, including biological, chemical, and physical risks. By assessing the likelihood and severity of these hazards, food producers can prioritize which risks need to be managed through the HACCP plan.

- Biological hazards: bacteria, viruses, parasites, fungi

- Chemical hazards: toxins, allergens, pesticides, cleaning agents

- Physical hazards: metal shards, glass, plastic particles

Principle 2: Determine the Critical Control Points (CCPs)

Once hazards have been identified, the next step is to determine the Critical Control Points (CCPs). These are stages in the food production process where control can be applied to prevent, eliminate, or reduce a food safety hazard to an acceptable level.

- CCP examples: cooking, cooling, packaging, metal detection

Principle 3: Establish Critical Limits

For each CCP, appropriate critical limits must be established. These are the maximum or minimum values to which biological, chemical, or physical parameters must be controlled to prevent, eliminate, or reduce the risk of food safety hazards.

- Temperature limits for cooking and cooling

- pH levels for acidity control

- Time limits for exposure to certain environments

Principle 4: Establish Monitoring Procedures

Effective monitoring of CCPs is essential to ensure that critical limits are consistently met. Monitoring procedures should be designed to detect loss of control at CCPs and provide documentation for verification purposes.

- Continuous temperature monitoring during cooking

- Regular pH testing during fermentation

- Visual inspections for physical contaminants

Principle 5: Establish Corrective Actions

When monitoring indicates that a CCP is not under control, corrective actions must be taken. These actions should aim to identify the cause of the problem, correct it, and prevent its recurrence.

- Discarding affected product

- Adjusting processes to bring CCP back under control

- Reassessing the HACCP plan to prevent future issues

Principle 6: Establish Verification Procedures

Verification procedures are necessary to confirm that the HACCP system is working effectively. This may include additional testing, review of monitoring records, and validation of critical limits and CCPs.

- Audits and inspections

- Review of records and documentation

- Product testing and sampling

Principle 7: Establish Record-Keeping and Documentation Procedures

Keeping detailed records is crucial for the success of a HACCP plan. Documentation should include the hazard analysis, CCP identification, critical limits, monitoring system, corrective actions, verification activities, and all procedures related to these principles.

- HACCP plan and hazard analysis documents

- Monitoring records for CCPs

- Documentation of corrective actions taken

Conclusion: The Importance of HACCP in Food Safety

In conclusion, the seven principles of HACCP provide a structured approach to food safety management. By identifying and controlling potential hazards at specific points in the production process, businesses can ensure the safety and quality of their food products. Implementing a robust HACCP plan not only protects consumers but also enhances the credibility and reputation of food producers.

For companies looking to incorporate high-quality protein ingredients into their food products, ETprotein offers a range of organic bulk vegan proteins and L-(+)-Ergothioneine that meet the highest standards of safety and quality. Their non-GMO, allergen-free proteins are ideal for various industries, including nutraceuticals, pharmaceuticals, and food and beverage.

Choose ETprotein for Your Protein Needs

ETprotein’s commitment to excellence ensures that their protein products are a reliable choice for businesses aiming to adhere to HACCP principles. With a focus on safety, quality, and customer satisfaction, ETprotein stands out as a leading supplier in the protein industry.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.