Smart Packaging: The Future of Food Safety

-

Table of Contents

- Smart Packaging: Revolutionizing Food Safety and Quality

- Understanding Smart Packaging

- The Role of Smart Packaging in Food Safety

- Technologies Driving Smart Packaging

- Case Studies and Examples of Smart Packaging in Action

- Statistics Highlighting the Impact of Smart Packaging

- Challenges and Considerations for Smart Packaging Adoption

- Conclusion: Embracing the Future of Food Safety

- ETprotein: Enhancing Nutrition with High-Quality Protein Products

Smart Packaging: Revolutionizing Food Safety and Quality

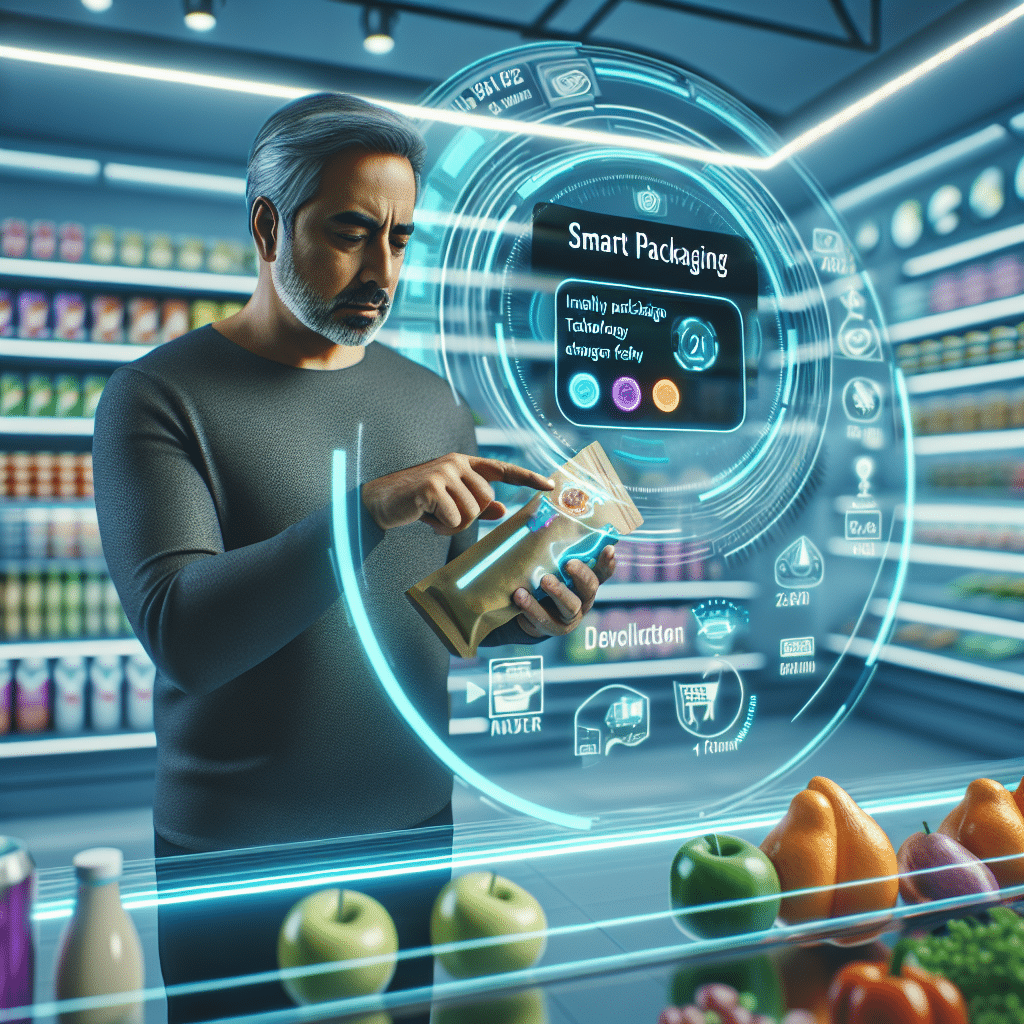

The food industry is undergoing a transformation, with smart packaging emerging as a key player in ensuring food safety and extending shelf life. This innovative approach to packaging not only helps in maintaining the quality of food products but also offers a new level of interaction between consumers and brands. In this article, we will delve into the world of smart packaging and its implications for the future of food safety.

Understanding Smart Packaging

Smart packaging refers to packaging systems that incorporate advanced technologies to provide benefits beyond conventional packaging methods. These technologies can include sensors, indicators, and data carriers, which work together to monitor the condition of the food, provide information, and even interact with consumers and supply chain stakeholders.

The Role of Smart Packaging in Food Safety

Food safety is a paramount concern for consumers and food producers alike. Smart packaging plays a crucial role in ensuring that food products are safe for consumption by:

- Monitoring the temperature and environment during transportation and storage to prevent spoilage.

- Providing freshness indicators that alert consumers to the quality of the product.

- Offering tamper-evident features that ensure the integrity of the food product.

- Enabling traceability throughout the supply chain to quickly identify and address potential contamination issues.

Technologies Driving Smart Packaging

Several technologies are at the forefront of smart packaging, each contributing to the safety and quality of food products:

- Time-Temperature Indicators (TTIs): These sensors provide visual cues about the product’s exposure to temperature over time, indicating potential spoilage.

- Radio-Frequency Identification (RFID): RFID tags can store and remotely retrieve data, aiding in tracking and tracing products throughout the supply chain.

- Gas Indicators: These sensors detect changes in the atmosphere inside the packaging, such as oxygen or carbon dioxide levels, which can signal spoilage or microbial growth.

- QR Codes and NFC: Quick Response (QR) codes and Near Field Communication (NFC) allow consumers to access detailed product information and verify authenticity using their smartphones.

Case Studies and Examples of Smart Packaging in Action

Several companies have already implemented smart packaging solutions with impressive results:

- A leading dairy company introduced TTIs in their products, resulting in a significant reduction in food waste and improved customer satisfaction.

- A meat producer employed RFID tags to ensure the traceability of their products, enhancing food safety and supply chain efficiency.

- A beverage brand utilized NFC-enabled caps that allowed consumers to access promotional content and verify product authenticity.

Statistics Highlighting the Impact of Smart Packaging

The impact of smart packaging on the food industry is supported by compelling statistics:

- According to a report by Grand View Research, the global smart packaging market size is expected to reach USD 26.7 billion by 2024, growing at a CAGR of 4.8%.

- A study by the University of Florida found that smart packaging could reduce food waste by up to 50% for certain products.

- Consumer surveys indicate that over 60% of shoppers are willing to pay more for packaging that ensures food safety and extends shelf life.

Challenges and Considerations for Smart Packaging Adoption

While smart packaging offers numerous benefits, there are challenges to its widespread adoption:

- Cost: The initial investment in smart packaging technologies can be high, potentially limiting its use to premium products.

- Complexity: Integrating advanced technologies into packaging requires specialized knowledge and infrastructure.

- Environmental Impact: The disposal and recycling of smart packaging materials must be carefully considered to minimize environmental harm.

Conclusion: Embracing the Future of Food Safety

Smart packaging represents a significant advancement in the way we approach food safety and quality. By leveraging cutting-edge technologies, the food industry can ensure that products are safe, fresh, and traceable from farm to fork. As consumers become more health-conscious and demand greater transparency, smart packaging will undoubtedly become an integral part of the food supply chain.

ETprotein: Enhancing Nutrition with High-Quality Protein Products

In the context of food safety and quality, ETprotein’s protein products stand out as an excellent example of how smart packaging can be used to preserve the integrity of nutritional supplements. Their range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) are packaged with care to ensure that they meet the highest standards of safety and efficacy. By choosing ETprotein, consumers and manufacturers can be confident in the quality and safety of their protein products.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.