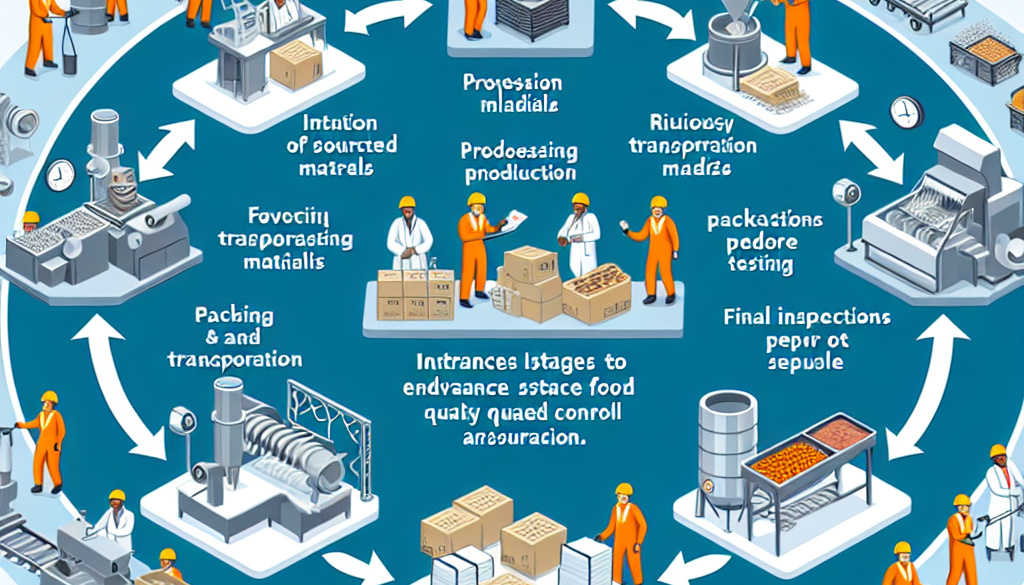

Stages to Ameliorate Food Quality Control & Assurance

-

Table of Contents

- Enhancing Food Quality Control & Assurance: Essential Stages for Safety and Trust

- Understanding Food Quality Control and Assurance

- Stage 1: Raw Material Sourcing and Supplier Verification

- Stage 2: Designing and Implementing Standard Operating Procedures (SOPs)

- Stage 3: Rigorous In-Process Quality Monitoring

- Stage 4: Final Product Testing and Verification

- Stage 5: Packaging Integrity and Label Accuracy

- Stage 6: Continuous Improvement and Consumer Feedback

- Conclusion: Commitment to Excellence in Food Quality

- ETprotein: Your Partner for High-Quality Protein Products

Enhancing Food Quality Control & Assurance: Essential Stages for Safety and Trust

Food quality control and assurance are critical components in the food production and distribution chain. Ensuring the safety, nutritional value, and consistency of food products is not only a regulatory requirement but also a moral imperative for food producers. With increasing consumer awareness and demand for high-quality food, the industry must adopt stringent measures to maintain and improve food quality. This article outlines the key stages to ameliorate food quality control and assurance, providing valuable insights for producers and consumers alike.

Understanding Food Quality Control and Assurance

Before delving into the stages of improving food quality control and assurance, it is essential to understand what these terms entail. Food quality control refers to the operational techniques and activities used to fulfill requirements for quality. Meanwhile, food quality assurance is a broader system that guarantees that the food meets certain standards and is safe for consumption. Together, they form a comprehensive approach to managing food quality and safety.

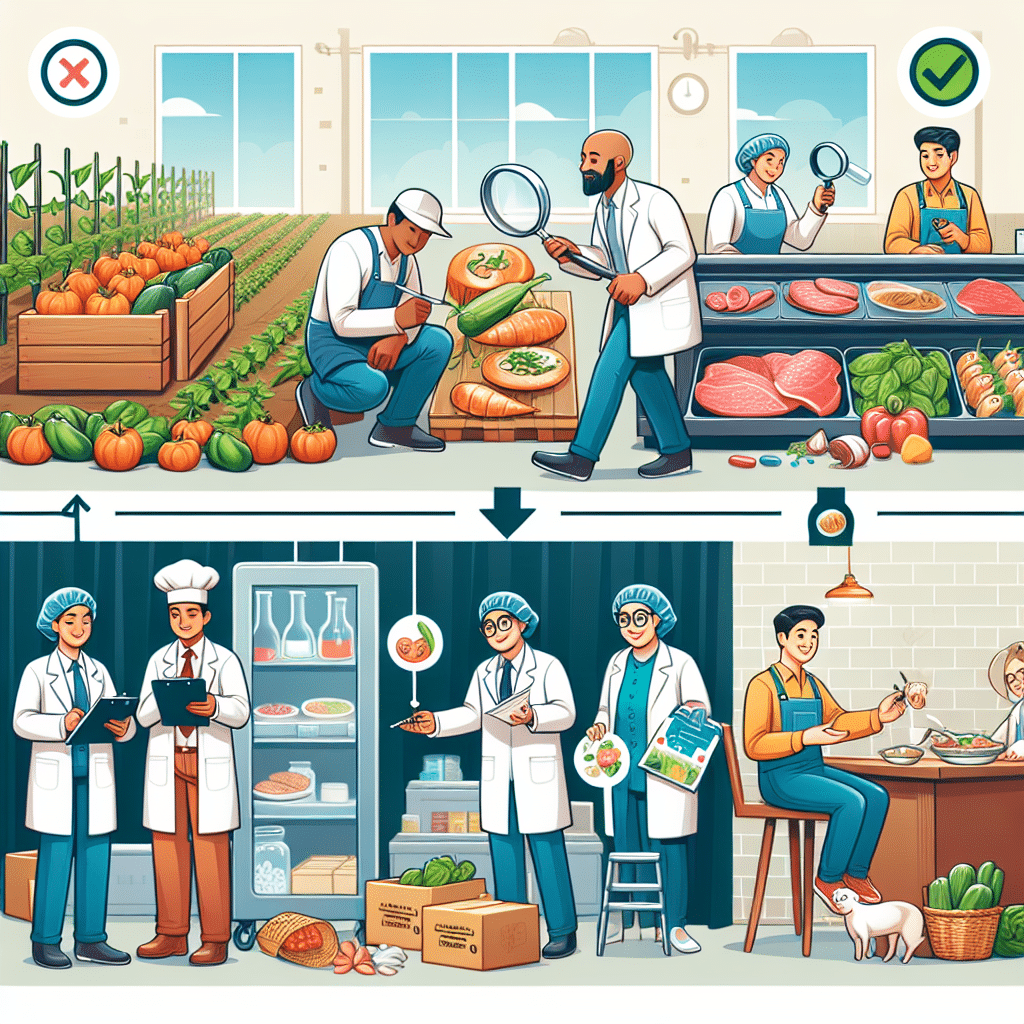

Stage 1: Raw Material Sourcing and Supplier Verification

- Conducting thorough supplier audits and assessments

- Implementing traceability systems for all ingredients

- Ensuring suppliers adhere to recognized food safety standards

Quality control begins with the ingredients. Sourcing raw materials from reputable suppliers who comply with safety standards is crucial. Implementing a robust supplier verification program can mitigate risks associated with contaminated or substandard ingredients.

Stage 2: Designing and Implementing Standard Operating Procedures (SOPs)

- Developing clear and detailed SOPs for each production process

- Training staff on SOPs to ensure consistency and compliance

- Regularly reviewing and updating SOPs to reflect best practices

Standard Operating Procedures are the backbone of quality control. They provide a blueprint for employees to follow, ensuring consistency and reducing the likelihood of errors. Regular training and updates are necessary to maintain a high standard of food quality.

Stage 3: Rigorous In-Process Quality Monitoring

- Implementing real-time monitoring systems for critical control points

- Conducting regular product testing during production

- Utilizing statistical process control to detect variations

Continuous monitoring during production helps to identify and correct issues promptly. By keeping a close eye on critical control points, manufacturers can ensure that the product meets quality standards at every stage of production.

Stage 4: Final Product Testing and Verification

- Performing microbiological and chemical analyses on finished products

- Ensuring products meet label claims for nutritional content

- Conducting sensory evaluations to assess taste, texture, and appearance

Before products reach the consumer, they must undergo rigorous testing to confirm that they are safe and meet all quality specifications. This stage is vital for catching any issues that may have been missed during the production process.

Stage 5: Packaging Integrity and Label Accuracy

- Using tamper-evident and protective packaging materials

- Verifying that labels contain accurate and regulatory-compliant information

- Ensuring proper storage conditions to maintain product quality

Packaging plays a significant role in maintaining food quality. It protects the product from contamination and damage, while accurate labeling provides consumers with essential information about the product’s contents and nutritional value.

Stage 6: Continuous Improvement and Consumer Feedback

- Gathering and analyzing consumer feedback for quality insights

- Implementing corrective actions based on feedback and quality audits

- Investing in research and development to enhance product quality

Quality assurance is an ongoing process. By actively seeking consumer feedback and conducting regular quality audits, companies can continuously improve their products. This not only enhances food safety but also builds consumer trust and loyalty.

Conclusion: Commitment to Excellence in Food Quality

In conclusion, improving food quality control and assurance involves a multi-stage approach that encompasses everything from raw material sourcing to consumer feedback. By rigorously applying these stages, food producers can ensure that their products are safe, nutritious, and of the highest quality. This commitment to excellence is essential for building consumer trust and maintaining a strong reputation in the competitive food industry.

ETprotein: Your Partner for High-Quality Protein Products

In the quest for superior food quality, protein products play a pivotal role. ETprotein company stands out as a leading provider of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT). Their extensive range of protein products, including organic rice protein, pea protein, and various seed proteins, are characterized by their neutral taste, non-GMO, and allergen-free attributes. With L-(+)-Ergothioneine purity over 98%, ETprotein caters to industries such as nutraceuticals, pharmaceuticals, cosmeceuticals, and food and beverage, ensuring that your protein needs are met with the highest standards of quality and safety.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.