Study on preparation of rice skin by enzymatic hydrolysis of rice residue protein

Explore the optimal enzymatic hydrolysis process for converting rice bran into bioactive rice peptides, enhancing food nutrition and sustainability.

Abstract

This study explores the optimal conditions for enzymatic hydrolysis of rice bran protein to prepare rice peptides. The results indicate that a hydrolysis condition of pH 8.5, temperature 55°C, and enzyme dosage of 2.0% for 3 hours yields a solution with over 37% content of peptides soluble in 5% TCA.

Keywords

Rice peptides; Rice bran; Enzymatic hydrolysis

Introduction

Bioactive peptides are known for their special physiological functions and can be derived from natural sources or through protein hydrolysis. Due to the low content and difficulty in extracting naturally occurring bioactive peptides, enzymatic hydrolysis of proteins has become a hot research topic. Rice protein, a high-quality plant protein rich in hydrophobic amino acids, is an ideal raw material for producing functional bioactive peptides. Hydrolyzed rice protein produces rice peptides with improved solubility, absorption, blood pressure reduction, and antioxidative properties, making them suitable for use in nutritional foods, convenience foods, instant beverages, and seasonings.

Rice bran, a by-product of fermentation and starch sugar industries, is concentrated in protein after starch extraction, making it an underutilized resource. This study aims to utilize rice bran for rice peptide production through enzymatic hydrolysis, providing foundational work for developing high-value products enriched with rice peptides.

Materials and Methods

- Materials and Reagents: Rice bran from Wuhan Weiquan Food Co., Ltd., with a moisture content of 62.0%, crude protein content of 56.3%, and total sugar content of 39.1%. Alcalase 2.4 L enzyme and various analytical grade chemicals were used.

- Equipment: Includes an electric stirrer, stainless steel thermostatic water bath, electric thermostatic drying oven, constant temperature incubator, pH meter, centrifuge, HPLC, colloid mill, and Kjeldahl nitrogen determination apparatus.

Experimental Methods:

- Pre-treatment of Rice Bran: Rice bran was mixed with water, passed through a colloid mill, and washed repeatedly to remove soluble sugars and increase protein content.

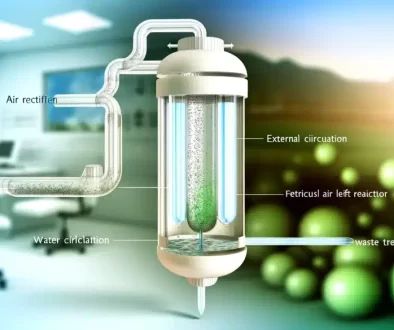

- Enzymatic Hydrolysis of Rice Bran Protein: The pre-treated rice bran was hydrolyzed under various conditions to identify optimal enzyme dosage, pH, temperature, and time for maximum peptide yield.

- Analytical Methods: Included measurements for moisture, total sugar, amino nitrogen, total nitrogen, and degree of hydrolysis (DH). The content of peptides soluble in 5% TCA was determined as a measure of hydrolysis efficiency.

Results and Analysis

- Pre-treatment Efficiency: Washing rice bran effectively reduced sugar content and increased protein concentration. After two washes, protein content increased from 56.3% to 74.9%.

- Optimization of Enzymatic Hydrolysis Conditions: Among various enzymes tested, Alcalase 2.4 L was chosen for its effective hydrolysis capability. The optimal conditions determined were pH 8.5, temperature 55°C, enzyme dosage of 2.0%, and hydrolysis time of 3 hours, under which the hydrolysis solution contained over 37% peptides soluble in 5% TCA.

- Control of Hydrolysis Degree: The study aimed to maximize protein hydrolysis into peptides while preventing excessive breakdown into free amino acids. A balance was achieved at the optimal conditions, ensuring high peptide yield with functional properties.

Conclusion

The study demonstrates the potential of using rice bran, a by-product of the MSG production process, for producing high-value rice peptides through enzymatic hydrolysis. Optimal hydrolysis conditions were established, leading to a significant yield of bioactive peptides. This process not only offers a way to valorize rice bran but also contributes to the sustainable production of functional food ingredients.

For more further detailed information of this research, feel free to contact our team for asssistance.

Original research by Tao Xingwu (Wuhan Institute of Technology, Wuhan, Hubei 430022) Article No. 1008-9578(2007)05-0022-02