Study on the process conditions for enzymatic preparation of rice protein peptides

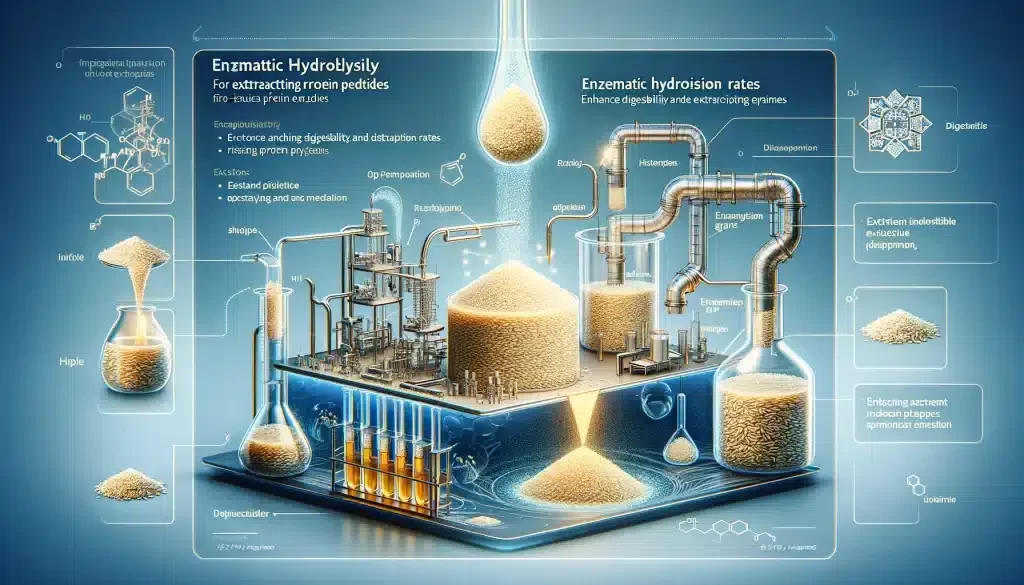

Discover the optimal enzymatic hydrolysis process for rice protein peptides, enhancing digestibility and extraction rates for industrial application.

Keywords: rice feed protein, rice peptide, ultrafine grinding, water washing, enzymatic hydrolysis, decolorization, desalination

Introduction

Enzymatic extraction is recognized for its efficiency in extracting a wide range of soluble, alcohol-soluble, and insoluble proteins. This method produces water-soluble small molecular active peptides and free amino acids through degradation and modification without damaging the biological functions of rice proteins or reducing the nutritional value of the extracts. Considering nutrition, flavor, and biological functions, enzymatic hydrolysis of rice feed protein powder to extract protein hydrolysates is the optimal method for preparing rice protein peptides. Enzymatic extraction under mild conditions facilitates the hydrolysis of protein polypeptide chains into shorter chains, enhancing protein digestibility while saving on alkali and water usage, thereby reducing energy consumption for removing water from the extract. The application of various new industrial separation technologies has created conditions favorable for industrial production and protein utilization.

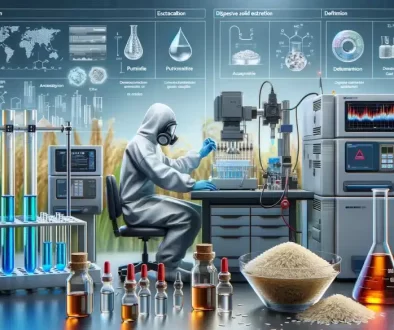

Materials and Methods

Analysis of Routine Components

- Protein content was measured using the micro-Kjeldahl method, referring to GB5009.5-85.

- Moisture was determined by the constant weight method at 105°C, referring to GB5512-85.

- Ash content was measured by ashing at 550–600°C, referring to GB/T5505-85.

- Fat content was determined using the Soxhlet extraction method, referring to GB5497-85.

Enzymatic Hydrolysis Process for Rice Feed Protein

Adequate amounts of pretreated rice feed protein powder were added to an enzyme reactor, deionized water was added in proportion, and the temperature was raised to a predetermined value in a constant temperature water bath. The pH was adjusted to a predetermined value using a NaOH solution (or HCl solution) under magnetic stirring, and a quantitative amount of protease (E/S, %) was added. After stirring evenly, the lid was covered to start hydrolysis. After hydrolysis, the mixture was heated to 90°C for 10 minutes to deactivate the enzymes, cooled, centrifuged at 4000 rpm for 20 minutes, and the supernatant was filtered to obtain rice feed protein peptide solution, which was stored in a refrigerator at 4°C.

Results and Discussion

- Hydrolysis by Different Proteases: The study compared the effects of alkaline protease, neutral protease, papain, and acid protease on the preparation of rice protein peptides. The extraction efficiency of various proteases was analyzed, and it was found that alkaline protease had the best extraction effect, followed by neutral protease and papain, while acid protease had a general effect.

- Single-factor Analysis of Enzyme Hydrolysis Conditions: The effects of temperature, pH, enzyme dosage, material-liquid ratio, and reaction time on the hydrolysis of rice feed protein by the enzymes were systematically analyzed to optimize the hydrolysis conditions.

Conclusion

The study identified the optimal types of enzymes for hydrolyzing rice feed protein as alkaline protease, neutral protease, and acid protease. It detailed the influence of various factors such as temperature, time, pH, enzyme dosage, and material-liquid ratio on the hydrolysis process by these enzymes. The best hydrolysis conditions for alkaline protease and neutral protease were determined to achieve the highest extraction rates of 60.85% and 32.87%, respectively. The research further optimized the composite enzyme hydrolysis process, determining the best conditions for the enzymatic reaction, which significantly improved the extraction rate of rice feed protein peptides to 74.58%. This comprehensive study not only advances our understanding of enzymatic hydrolysis but also provides a valuable methodology for the industrial extraction and utilization of rice protein peptides.

This article summarizes the key findings and methodologies of the original Chinese article on the enzymatic preparation of rice protein peptides, adhering to the structure and depth of the original document while making it accessible to an English-speaking scientific audience.

For more further detailed information of this research, feel free to contact our team for asssistance.

The original research is done by HE Qiangfei,GUO Guanxin,YU Qiusheng(School of Food Science, Jiangnan University, Wuxi,214122, China) The ariticle ID is: doi: 10.7666/d.y1397665