Sustainability in Manufacturing: Improving and Reducing Food Waste

-

Table of Contents

- Sustainability in Manufacturing: Strategies to Reduce Food Waste

- Understanding the Impact of Food Waste

- Strategies for Reducing Food Waste in Manufacturing

- Technological Innovations in Food Waste Management

- Regulatory Frameworks and Incentives

- Consumer Awareness and Demand for Sustainable Products

- Conclusion: The Path Forward for Sustainable Manufacturing

- ETprotein: Commitment to Sustainability and Quality

Sustainability in Manufacturing: Strategies to Reduce Food Waste

Food waste is a global issue with significant environmental, economic, and social implications. In the manufacturing sector, the efficient use of resources is not only a matter of corporate responsibility but also a strategic imperative for sustainable growth. This article explores the various strategies and innovations that manufacturers can adopt to reduce food waste and improve sustainability in their operations.

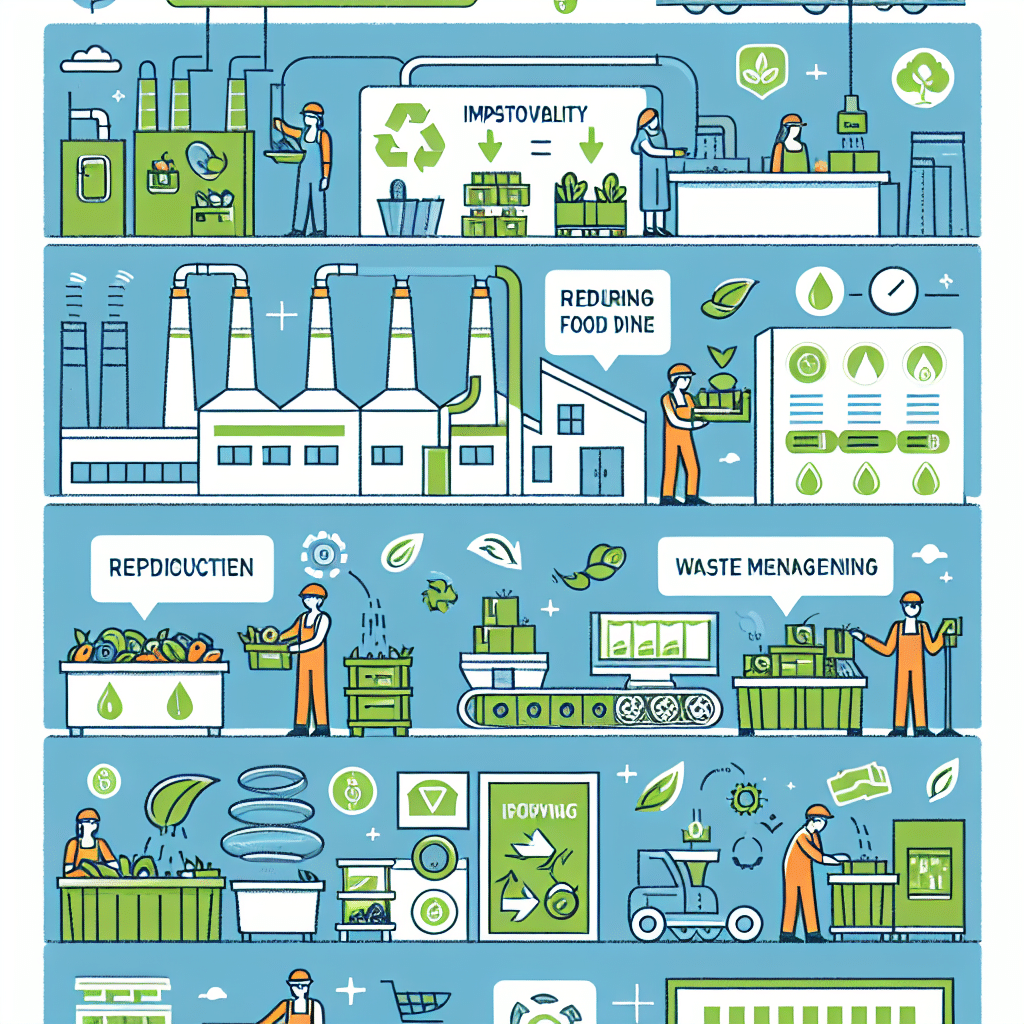

Understanding the Impact of Food Waste

Food waste occurs at every stage of the supply chain, from production to consumption. According to the Food and Agriculture Organization (FAO) of the United Nations, approximately one-third of all food produced for human consumption is lost or wasted. This translates to a staggering 1.3 billion tonnes per year. The environmental cost is equally alarming, with wasted food accounting for about 8% of global greenhouse gas emissions.

Strategies for Reducing Food Waste in Manufacturing

Manufacturers have a pivotal role to play in reducing food waste. By implementing the following strategies, they can make significant strides towards sustainability:

- Efficient Inventory Management: By using data analytics and forecasting tools, manufacturers can optimize their inventory levels, reducing the likelihood of overproduction and spoilage.

- Process Optimization: Streamlining manufacturing processes to minimize waste during production can have a substantial impact. This includes improving equipment efficiency and adopting lean manufacturing principles.

- Supply Chain Collaboration: Working closely with suppliers and distributors ensures better alignment of production schedules with demand, thus reducing waste.

- Upcycling and Repurposing: Finding innovative ways to use by-products or unsellable goods can turn waste into valuable resources.

- Investment in Preservation Technologies: Advanced preservation methods, such as modified atmosphere packaging or vacuum sealing, can extend the shelf life of food products.

Technological Innovations in Food Waste Management

Technology plays a crucial role in reducing food waste. Innovations such as the Internet of Things (IoT) for real-time tracking of inventory, Artificial Intelligence (AI) for demand forecasting, and blockchain for enhancing supply chain transparency are revolutionizing the way manufacturers operate.

Regulatory Frameworks and Incentives

Governments worldwide are recognizing the importance of reducing food waste and are implementing policies to encourage sustainable practices. Tax incentives, grants, and regulations such as organic waste bans are pushing manufacturers to adopt more sustainable practices.

Consumer Awareness and Demand for Sustainable Products

Consumer awareness is driving demand for sustainably produced goods. Manufacturers that prioritize waste reduction and sustainability in their branding and product development can gain a competitive edge in the market.

Conclusion: The Path Forward for Sustainable Manufacturing

Reducing food waste in manufacturing is not only an ethical and environmental necessity but also a business opportunity. By adopting efficient practices, investing in technology, and responding to consumer demand, manufacturers can lead the way in creating a more sustainable future.

ETprotein: Commitment to Sustainability and Quality

In line with the principles of sustainability, ETprotein offers a range of high-quality protein products that support the health and wellness industry. Their organic bulk vegan proteins and L-(+)-Ergothioneine are produced with a commitment to environmental responsibility and ethical sourcing. By choosing ETprotein, manufacturers and consumers can contribute to a more sustainable food system while benefiting from superior nutritional products.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.