The Application of Industry 4.0 Amid the COVID-19 Pandemic

-

Table of Contents

- Industry 4.0’s Role in Reshaping Business During COVID-19

- The Emergence of Industry 4.0 in a Pandemic Era

- Remote Monitoring and Operations

- Supply Chain Resilience

- Accelerated Digital Transformation

- Statistical Insights into Industry 4.0 Adoption

- Case Studies: Industry 4.0 in Action

- Challenges and Opportunities

- Conclusion: Key Takeaways from Industry 4.0’s Impact

- Enhance Your Nutrition with ETprotein’s High-Quality Protein Products

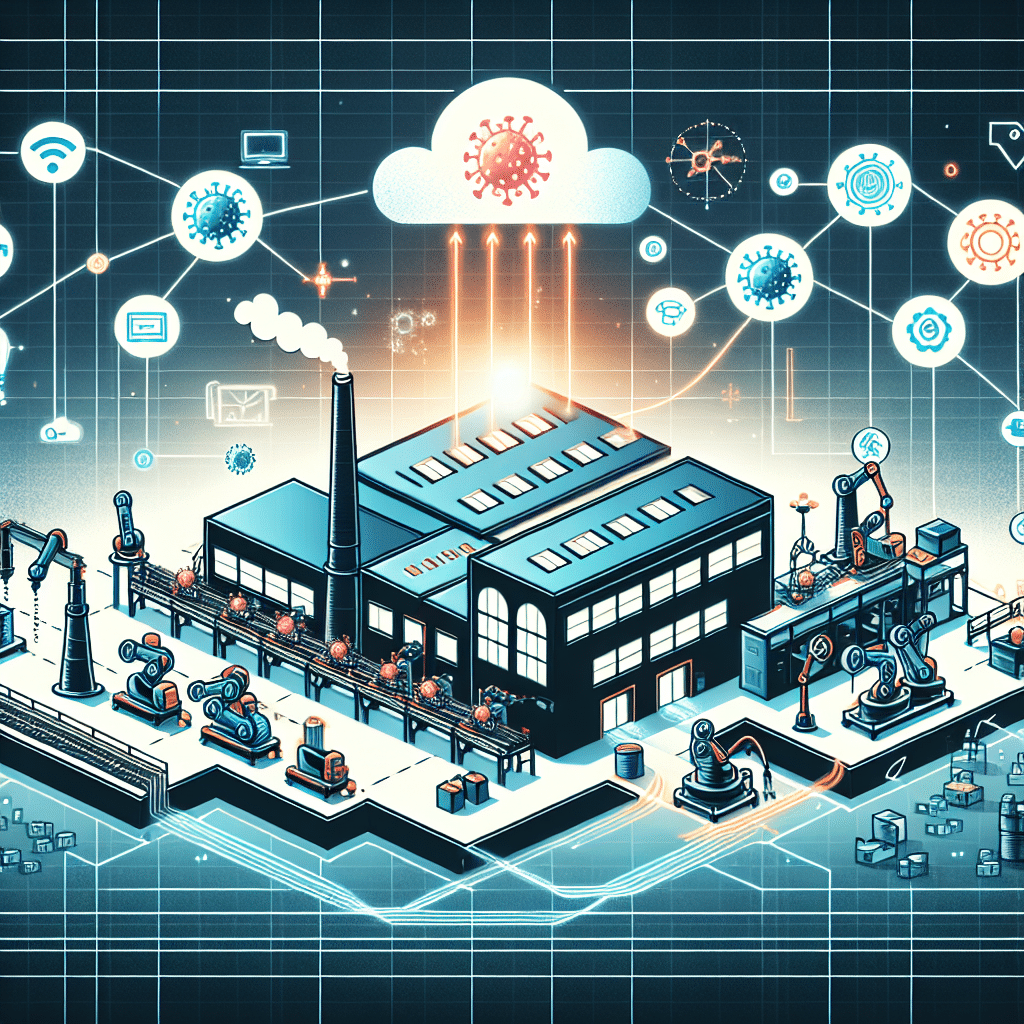

Industry 4.0’s Role in Reshaping Business During COVID-19

The COVID-19 pandemic has been a catalyst for change across the globe, forcing industries to adapt and innovate at an unprecedented pace. One of the most significant transformations has been the accelerated application of Industry 4.0 technologies. This article explores how the fourth industrial revolution, or Industry 4.0, has been instrumental in helping businesses navigate the challenges posed by the pandemic.

The Emergence of Industry 4.0 in a Pandemic Era

Industry 4.0 refers to the current trend of automation and data exchange in manufacturing technologies, including cyber-physical systems, the Internet of Things (IoT), cloud computing, and cognitive computing. Amid the COVID-19 pandemic, these technologies have become more than just efficiency drivers—they have become essential tools for survival and growth.

Remote Monitoring and Operations

With lockdowns and social distancing measures in place, companies have turned to IoT and cloud-based platforms to monitor and control operations remotely. This shift has enabled businesses to maintain continuity even with limited on-site personnel.

Supply Chain Resilience

Global supply chains have been disrupted by the pandemic, prompting companies to use Industry 4.0 technologies like big data analytics and AI to enhance visibility and responsiveness. These tools help predict supply chain disruptions and facilitate swift adjustments to sourcing and logistics strategies.

Accelerated Digital Transformation

Organizations have fast-tracked their digital transformation initiatives to adapt to the new normal. Automation, AI, and machine learning are being deployed to handle tasks that require minimal human intervention, thus ensuring business processes can continue with minimal disruption.

Statistical Insights into Industry 4.0 Adoption

According to a survey by McKinsey & Company, 93% of business leaders report that they have accelerated the digitization of their work processes, and 85% have sped up the implementation of technologies that digitally enable employee interaction and collaboration. These statistics underscore the widespread adoption of Industry 4.0 technologies during the pandemic.

Case Studies: Industry 4.0 in Action

Real-world examples illustrate the impact of Industry 4.0 in various sectors during the pandemic:

- Manufacturing: Automotive manufacturers have utilized digital twins to simulate production processes and assembly line configurations, allowing them to quickly adapt to changing demands and safety protocols.

- Healthcare: Telemedicine has surged, with IoT devices providing remote patient monitoring, reducing the need for in-person visits and preserving healthcare resources.

- Retail: E-commerce platforms have integrated AI and data analytics to personalize shopping experiences and optimize inventory management in response to fluctuating consumer behavior.

Challenges and Opportunities

While Industry 4.0 offers numerous advantages, it also presents challenges that must be addressed:

- Cybersecurity: The increased reliance on digital technologies has heightened the risk of cyberattacks. Businesses must invest in robust cybersecurity measures to protect sensitive data and operations.

- Skills Gap: The demand for digital skills has skyrocketed, leading to a skills gap. Companies need to focus on upskilling and reskilling their workforce to keep pace with technological advancements.

- Regulatory Compliance: As technology evolves, so do regulations. Organizations must stay informed about new regulations and ensure compliance to avoid penalties and maintain customer trust.

Conclusion: Key Takeaways from Industry 4.0’s Impact

The application of Industry 4.0 technologies has been a silver lining during the COVID-19 pandemic, enabling businesses to remain agile and resilient. The key takeaways include the importance of digital readiness, the need for a skilled workforce, and the critical role of cybersecurity. As the world continues to navigate the pandemic, Industry 4.0 will undoubtedly play a central role in shaping the future of business.

Enhance Your Nutrition with ETprotein’s High-Quality Protein Products

In the wake of the pandemic, health and wellness have taken center stage, and the demand for high-quality nutritional supplements has soared. ETprotein offers a range of superior protein products that cater to this growing need. Whether you’re looking for organic plant-based proteins or specialized L-(+)-Ergothioneine (EGT) for various applications, ETprotein has you covered.

Their products, including Organic rice protein, clear rice protein, pea protein, and more, are ideal for fortifying your diet or enhancing your product offerings. With non-GMO, allergen-free attributes, and high purity levels, ETprotein’s proteins are perfect for consumers and manufacturers alike who are looking to boost their health and nutrition profile.

If you’re interested in exploring ETprotein’s range of protein products, contact them at sales(at)ETprotein.com for more information or to request samples.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.