The Role of Smart Robotics in Bakery Manufacturing Process

-

Table of Contents

- Smart Robotics Revolutionizing Bakery Manufacturing Processes

- The Emergence of Robotics in Bakery Manufacturing

- Enhancing Efficiency and Productivity

- Consistency and Quality Control

- Addressing Labor Shortages and Safety

- Challenges in Implementing Smart Robotics

- The Future of Robotics in Bakery Manufacturing

- Conclusion

- Enhance Your Bakery Products with ETprotein’s High-Quality Proteins

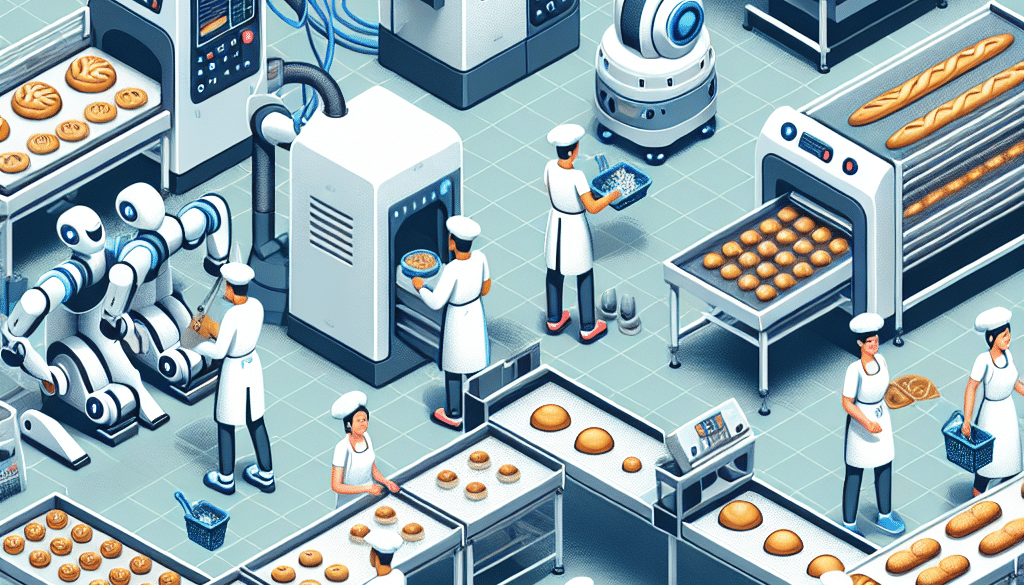

Smart Robotics Revolutionizing Bakery Manufacturing Processes

The bakery industry has been undergoing a significant transformation, with smart robotics playing a pivotal role in modernizing manufacturing processes. The integration of advanced robotics into bakery production lines is enhancing efficiency, consistency, and safety, while also addressing labor shortages and the growing demand for high-quality baked goods. This article explores the role of smart robotics in the bakery manufacturing process, highlighting the benefits, challenges, and future prospects.

The Emergence of Robotics in Bakery Manufacturing

Robotics technology has been steadily making its way into various sectors, and the bakery industry is no exception. The use of robots in bakery manufacturing is not entirely new, but the sophistication and capabilities of these machines have grown exponentially in recent years. From dough mixing to packaging, smart robotics are now involved in almost every step of the production process.

Enhancing Efficiency and Productivity

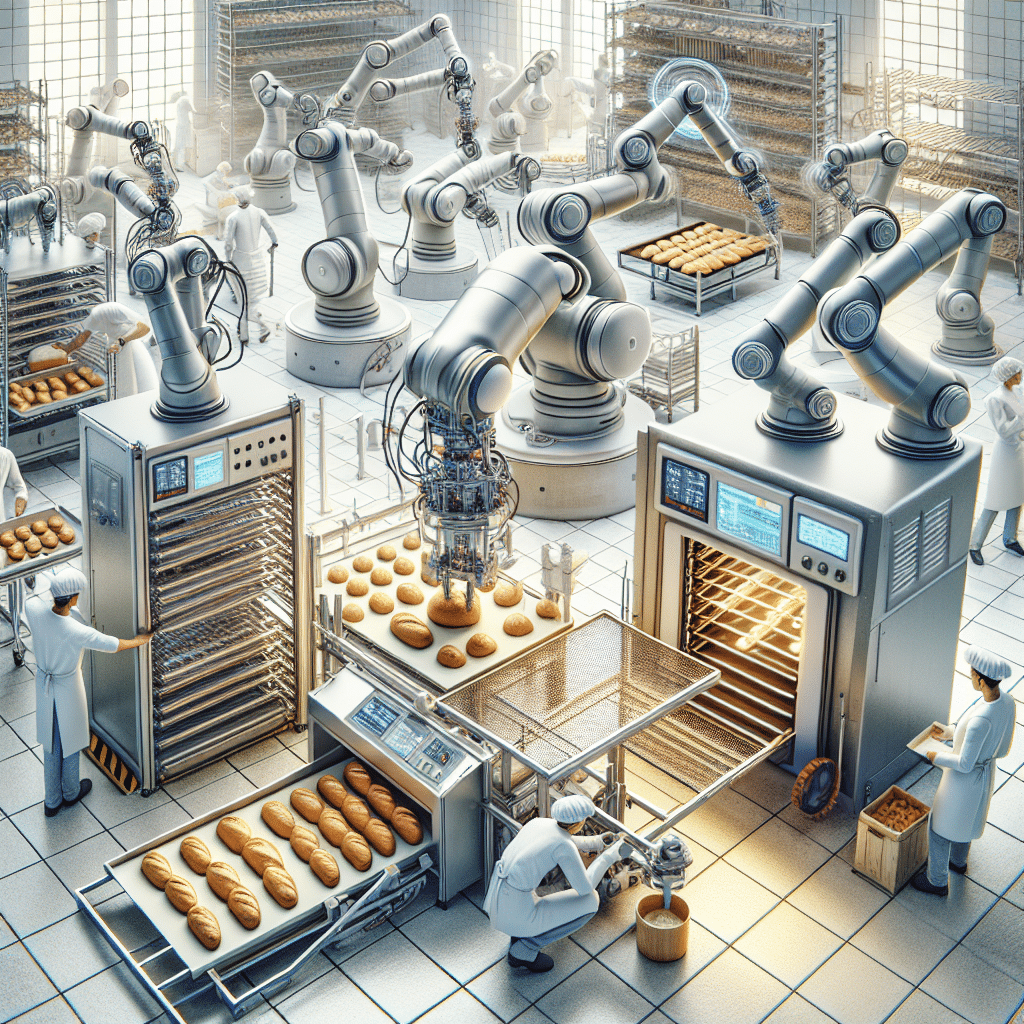

One of the primary advantages of incorporating robotics into bakery manufacturing is the significant boost in efficiency and productivity. Robots can operate 24/7 without the need for breaks, leading to uninterrupted production cycles. This constant operation is crucial for meeting the high demand for baked goods without compromising on quality.

- Automated mixing and kneading machines ensure precise ingredient handling and dough consistency.

- Robotic arms can decorate cakes and pastries with high precision, replicating intricate designs flawlessly.

- Packaging robots can sort, pack, and palletize products at speeds far beyond human capabilities.

Consistency and Quality Control

Smart robotics also play a vital role in maintaining consistency and quality control in bakery products. With their ability to perform tasks with exact precision, robots ensure that each product meets the same high standards.

- 3D vision systems enable robots to inspect baked goods for defects or inconsistencies.

- Automated portioning ensures that each product is uniform in size and weight.

- Robots equipped with sensors can monitor baking conditions, adjusting in real-time to maintain product quality.

Addressing Labor Shortages and Safety

The bakery industry often faces labor shortages, especially during peak seasons. Robotics can fill this gap by taking on repetitive and physically demanding tasks, allowing human workers to focus on more skilled and creative aspects of the production process.

- Robots can work in hazardous conditions, such as extreme temperatures, reducing the risk of injury to human workers.

- By handling heavy lifting and repetitive motions, robots help prevent workplace injuries and strain.

- Automation can also help to reduce the need for overtime, leading to a better work-life balance for employees.

Challenges in Implementing Smart Robotics

Despite the numerous benefits, there are challenges associated with integrating smart robotics into bakery manufacturing. The initial investment can be substantial, and there is a need for skilled personnel to manage and maintain these sophisticated systems. Additionally, the transition to a more automated production line may require significant changes to existing workflows and processes.

The Future of Robotics in Bakery Manufacturing

The future of robotics in the bakery industry looks promising, with ongoing advancements in artificial intelligence (AI) and machine learning further enhancing the capabilities of these systems. As technology continues to evolve, we can expect to see even more innovative applications of robotics in bakery manufacturing, such as:

- Robots with advanced AI that can adapt to new tasks without manual reprogramming.

- Increased collaboration between robots and human workers, leading to more efficient and flexible production lines.

- Greater use of data analytics to optimize production processes and reduce waste.

Conclusion

The integration of smart robotics into bakery manufacturing is revolutionizing the industry, offering numerous benefits such as increased efficiency, consistent quality, and improved safety. While challenges exist, the potential for growth and innovation in this area is vast. As technology continues to advance, we can expect to see even more sophisticated robotic systems becoming integral to the bakery manufacturing process.

Enhance Your Bakery Products with ETprotein’s High-Quality Proteins

If you’re looking to improve the nutritional profile of your bakery products, consider incorporating protein powders from ETprotein. Their extensive range of organic and vegan-friendly proteins can help you create healthier baked goods that cater to the growing market of health-conscious consumers.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.