Thermal Processing of High-Protein Foods: Ensuring Safety

-

Table of Contents

- Thermal Processing of High-Protein Foods: Ensuring Safety and Quality

- Understanding Thermal Processing

- Challenges in High-Protein Food Processing

- Optimizing Thermal Processing for Safety

- Case Studies and Examples

- Advancements in Thermal Processing Technology

- Regulatory Considerations and Standards

- Ensuring Quality Alongside Safety

- Conclusion: Balancing Safety and Quality in High-Protein Foods

- Discover ETprotein’s High-Quality Protein Products

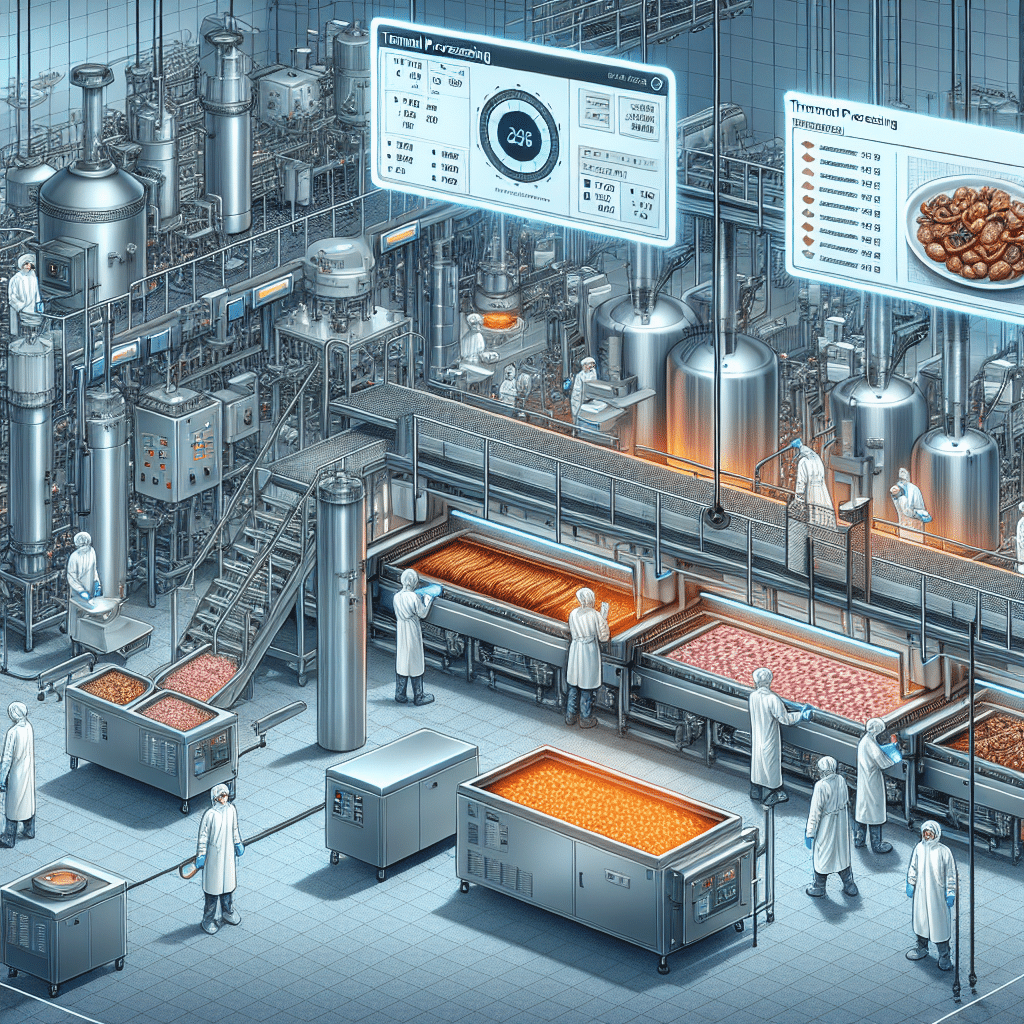

Thermal Processing of High-Protein Foods: Ensuring Safety and Quality

High-protein foods are an essential part of a balanced diet, contributing to muscle repair, immune function, and overall health. However, the safety and quality of these foods are paramount, as they are susceptible to microbial contamination and quality degradation. Thermal processing is a critical method used to ensure the safety of high-protein foods while maintaining their nutritional value. This article delves into the intricacies of thermal processing, exploring how it can be optimized to safeguard high-protein food products.

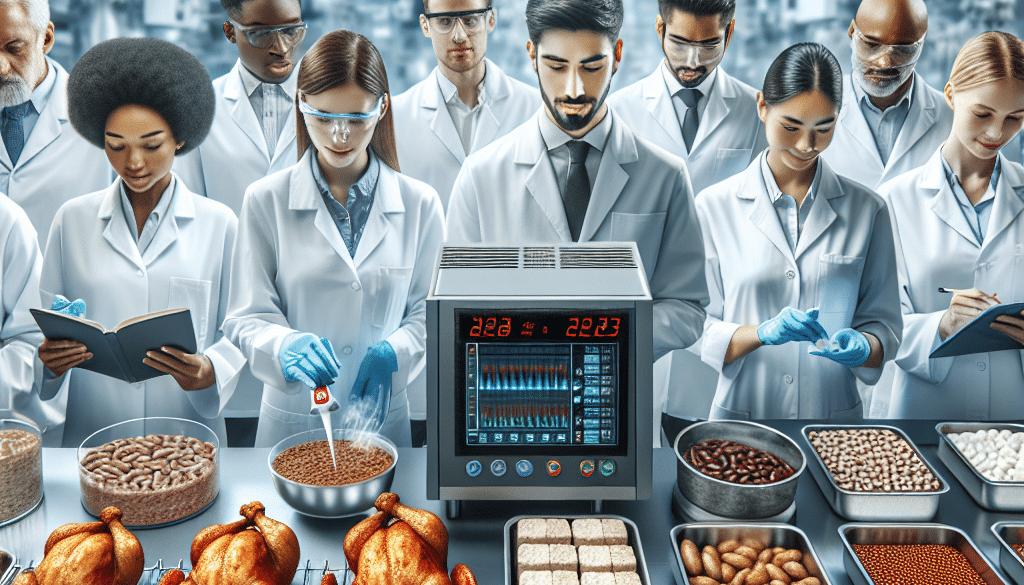

Understanding Thermal Processing

Thermal processing involves the application of heat to food products to destroy pathogenic microorganisms and enzymes that can cause spoilage. It is a widely used method for extending the shelf life of foods and ensuring their safety for consumption. The process can vary from pasteurization to sterilization, depending on the level of heat applied and the intended shelf life of the product.

Challenges in High-Protein Food Processing

High-protein foods, such as meat, dairy, legumes, and certain plant-based alternatives, present unique challenges when it comes to thermal processing. These include:

- Protein denaturation: High temperatures can cause proteins to unfold and lose their functional properties.

- Maillard reactions: The combination of proteins and reducing sugars at high temperatures can lead to undesirable flavors and colors.

- Microbial resistance: Certain pathogens in high-protein foods may be more resistant to heat, requiring careful calibration of thermal processes.

Optimizing Thermal Processing for Safety

To ensure the safety of high-protein foods, thermal processing must be carefully controlled. This involves:

- Identifying the most heat-resistant pathogens likely to be present in the food and determining the thermal death time (TDT) for these organisms.

- Applying the appropriate time-temperature combination to ensure the destruction of these pathogens without compromising the food’s quality.

- Using rapid cooling methods post-thermal processing to prevent the outgrowth of any surviving microorganisms.

Case Studies and Examples

Several case studies highlight the importance of thermal processing in ensuring the safety of high-protein foods:

- The 1994 Salmonella Enteritidis outbreak in ice cream, which was traced back to improperly pasteurized egg products, underscores the need for stringent thermal processing controls.

- The successful implementation of ultra-high temperature (UHT) processing in milk production has significantly reduced the risk of milk-borne illnesses while extending shelf life.

Advancements in Thermal Processing Technology

Technological advancements have led to more precise and efficient thermal processing methods, such as:

- Ohmic heating: This method uses electrical resistance to heat foods quickly and uniformly, reducing the risk of under-processing.

- High-pressure processing (HPP): While not strictly thermal, HPP can be used in conjunction with mild heat to inactivate pathogens in high-protein foods without significant quality loss.

Regulatory Considerations and Standards

Regulatory bodies such as the FDA and USDA have established guidelines and standards for the thermal processing of high-protein foods. These regulations are designed to ensure that all commercially available products are safe for consumption. Compliance with these standards is not only a legal requirement but also a commitment to consumer safety.

Ensuring Quality Alongside Safety

While safety is the primary concern, maintaining the quality of high-protein foods during thermal processing is also crucial. This includes:

- Optimizing processing parameters to minimize nutrient loss and sensory changes.

- Implementing quality control measures to monitor changes in texture, flavor, and color.

- Exploring alternative or complementary processing methods that can reduce the need for high temperatures.

Conclusion: Balancing Safety and Quality in High-Protein Foods

Thermal processing is a vital tool in ensuring the safety of high-protein foods, but it must be carefully balanced with quality preservation. By understanding the unique challenges of high-protein foods and leveraging advancements in technology, food processors can deliver safe and high-quality products to consumers. Ongoing research and adherence to regulatory standards will continue to play a critical role in the thermal processing landscape.

Discover ETprotein’s High-Quality Protein Products

For those seeking premium protein ingredients, ETprotein offers a range of high-quality, organic bulk vegan protein and plant proteins. Their products, including Organic rice protein, clear rice protein, pea protein, clear pea protein, and more, are ideal for various applications in the food and beverage industry. With a commitment to non-GMO, allergen-free, and neutral-tasting protein sources, ETprotein is a trusted supplier for businesses looking to enhance their product offerings with safe and nutritious protein options.

About ETprotein:

ETprotein, a reputable protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.