Thermal Stability Tests for Protein Ingredients: Quality Assurance

-

Table of Contents

- Thermal Stability Testing for Protein Ingredients: Ensuring Quality Assurance

- Understanding Thermal Stability in Proteins

- Why Thermal Stability Testing is Essential

- Methods of Thermal Stability Testing

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

- Circular Dichroism (CD) Spectroscopy

- Dynamic Light Scattering (DLS)

- Case Studies and Examples

- Implications for Product Development and Quality

- Statistics and Market Trends

- Conclusion: The Importance of Thermal Stability Testing

- Discover Quality Protein Ingredients with ETprotein

Thermal Stability Testing for Protein Ingredients: Ensuring Quality Assurance

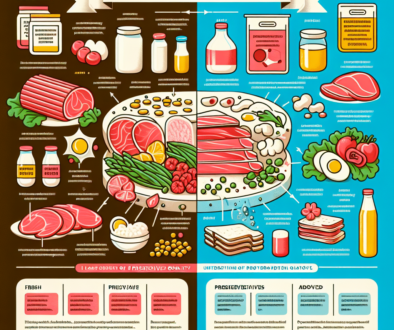

Protein ingredients are fundamental components in a wide array of food products, pharmaceuticals, and nutraceuticals. Their quality and stability are crucial for the safety, efficacy, and sensory attributes of the final products. Thermal stability tests are essential quality assurance measures that help manufacturers ensure that protein ingredients can withstand processing, storage, and usage conditions without degradation or loss of functionality. This article delves into the importance of thermal stability tests for protein ingredients, the methodologies used, and the implications for product quality.

Understanding Thermal Stability in Proteins

Thermal stability refers to the ability of a protein to maintain its structural integrity and functionality when exposed to heat. Proteins are complex molecules that can denature or unfold when subjected to high temperatures, leading to a loss of biological activity and, potentially, the development of off-flavors or reduced solubility. Therefore, assessing the thermal stability of protein ingredients is a critical step in quality assurance.

Why Thermal Stability Testing is Essential

- Product Consistency: Ensuring that protein ingredients can withstand processing temperatures is vital for consistent product quality.

- Shelf-life Determination: Thermal stability data can help predict the shelf-life of products, particularly those exposed to varying storage conditions.

- Consumer Safety: By confirming that proteins remain stable under thermal stress, manufacturers can prevent the formation of harmful compounds.

- Regulatory Compliance: Adhering to regulatory standards often requires evidence of ingredient stability.

Methods of Thermal Stability Testing

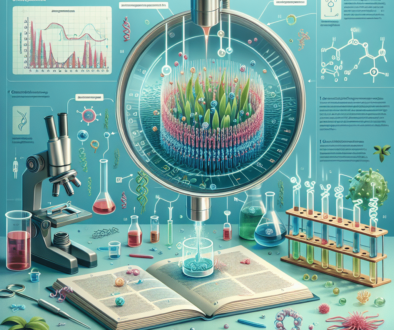

Several techniques are employed to assess the thermal stability of protein ingredients, each with its own set of advantages and applications.

Differential Scanning Calorimetry (DSC)

DSC is a widely used method that measures the heat flow associated with protein denaturation as a function of temperature. It provides precise data on the thermal transition points of proteins, which are indicative of their stability.

Thermogravimetric Analysis (TGA)

TGA tracks the weight loss of a protein sample as it is heated, offering insights into the thermal stability and composition of the protein ingredient.

Circular Dichroism (CD) Spectroscopy

CD spectroscopy analyzes the secondary structure of proteins by measuring their optical activity. Changes in CD spectra upon heating can reveal information about protein folding and stability.

Dynamic Light Scattering (DLS)

DLS assesses the size distribution of protein particles in solution. Aggregation upon heating, which affects particle size, can be monitored to evaluate thermal stability.

Case Studies and Examples

Real-world applications of thermal stability testing provide valuable insights into its importance:

- A study on whey protein isolate demonstrated how DSC could predict the protein’s behavior during thermal processing, aiding in the development of heat-stable formulations.

- Research on plant-based proteins, such as pea and rice protein, has utilized thermal stability data to optimize processing conditions for alternative meat products.

Implications for Product Development and Quality

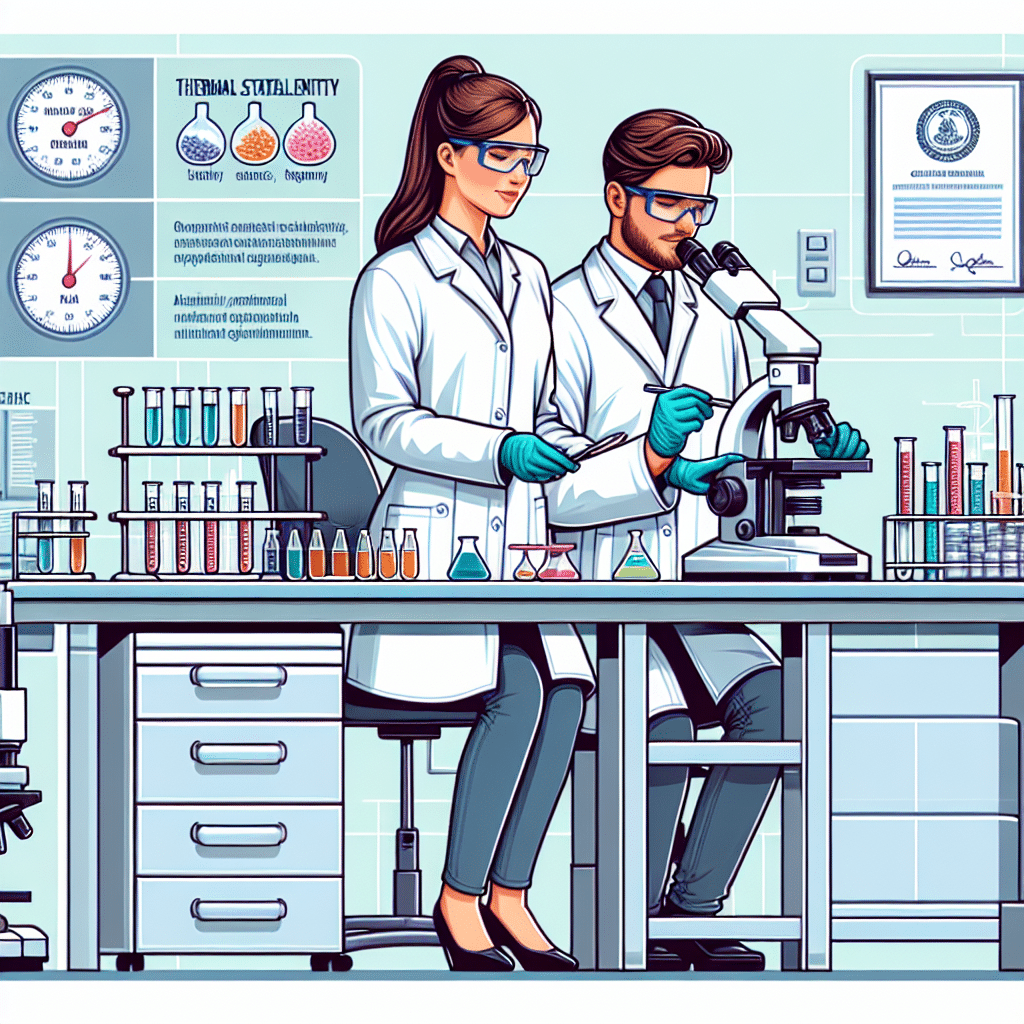

Thermal stability tests are not just a regulatory requirement; they are a cornerstone of product development and quality control. By understanding the thermal behavior of protein ingredients, manufacturers can:

- Design processing methods that preserve protein functionality.

- Develop products that maintain their quality under various conditions.

- Enhance the nutritional value of products by preventing protein degradation.

Statistics and Market Trends

The demand for protein ingredients is on the rise, with the global protein ingredient market projected to reach significant growth by 2025. This growth is driven by consumer interest in health and wellness, as well as the popularity of plant-based proteins. As the market expands, the role of thermal stability testing becomes increasingly important to maintain high standards of product quality and safety.

Conclusion: The Importance of Thermal Stability Testing

Thermal stability testing for protein ingredients is a critical aspect of quality assurance that ensures the safety, functionality, and shelf-life of a wide range of products. By employing various analytical techniques, manufacturers can gain valuable insights into the behavior of proteins under thermal stress, leading to better product development and consumer satisfaction. As the demand for protein-rich and plant-based products continues to grow, the importance of these tests will only increase.

Discover Quality Protein Ingredients with ETprotein

If you’re in search of high-quality protein ingredients that have undergone rigorous thermal stability testing, look no further than ETprotein. Their extensive range of organic and plant-based proteins, including rice, pea, pumpkin seed, and sunflower seed proteins, are designed to meet the highest standards of quality and functionality.

ETprotein’s commitment to non-GMO, allergen-free products ensures that you receive ingredients that not only meet your specifications but also cater to consumer demands for clean and sustainable nutrition. Whether you’re formulating for the food and beverage industry, sports nutrition, or health and wellness products, ETprotein has the expertise and resources to support your needs.

Contact ETprotein today to learn more about their protein offerings and how they can enhance your product portfolio.

About ETprotein:

ETprotein, a reputable protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein etc. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.