Transitioning to a Connected and Continuous Manufacturing Ecosystem

-

Table of Contents

- Connected and Continuous Manufacturing Ecosystem: The Future of Production

- The Rise of the Connected and Continuous Manufacturing Ecosystem

- Benefits of a Connected and Continuous Manufacturing Ecosystem

- Challenges in Transitioning to a Connected Ecosystem

- Strategies for a Successful Transition

- Conclusion: Embracing the Future of Manufacturing

- ETprotein: Your Partner in Nutritional Excellence

Connected and Continuous Manufacturing Ecosystem: The Future of Production

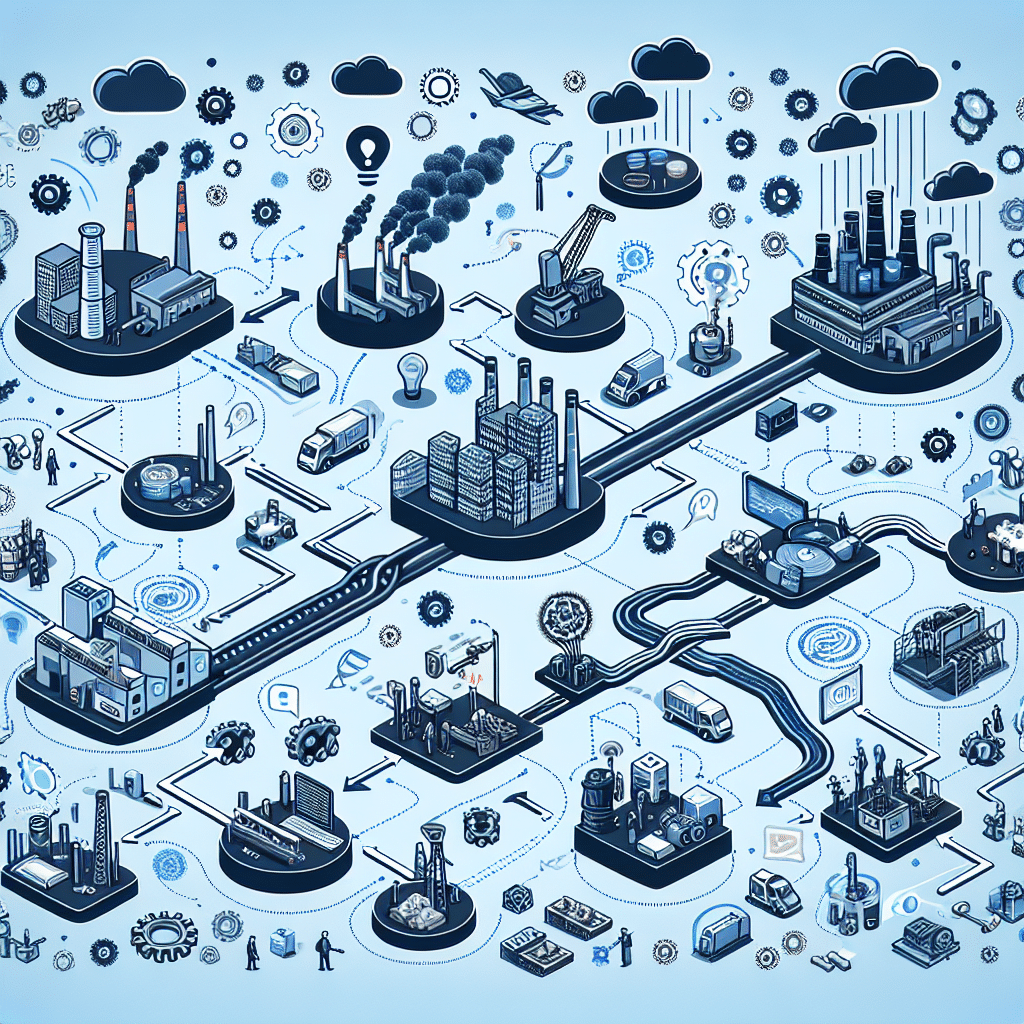

The manufacturing industry is undergoing a significant transformation, driven by technological advancements and the need for more efficient, sustainable, and responsive production methods. The transition to a connected and continuous manufacturing ecosystem represents a paradigm shift from traditional, linear manufacturing processes to a more integrated and flexible approach. This article explores the key aspects of this transition, its benefits, and the challenges it presents.

The Rise of the Connected and Continuous Manufacturing Ecosystem

Connected and continuous manufacturing is characterized by a seamless integration of systems, processes, and data across the entire production lifecycle. This approach leverages the Internet of Things (IoT), artificial intelligence (AI), machine learning, and other cutting-edge technologies to create a manufacturing environment that is more agile, transparent, and efficient.

- Integration of IoT: IoT devices collect and transmit data in real-time, enabling manufacturers to monitor and control production processes remotely.

- Application of AI and Machine Learning: These technologies analyze vast amounts of data to optimize operations, predict maintenance needs, and enhance decision-making.

- Advanced Analytics: Data analytics tools provide insights into production trends, helping to improve product quality and reduce waste.

- Flexible Production Lines: Modular and adaptable production systems can quickly switch between different products or adjust to changes in demand.

According to a report by the World Economic Forum, factories that have successfully implemented connected and continuous manufacturing have seen up to a 50% reduction in machine downtime, a 20-50% increase in labor productivity, and a 10-30% gain in energy efficiency.

Benefits of a Connected and Continuous Manufacturing Ecosystem

The transition to a connected and continuous manufacturing ecosystem offers numerous benefits that can significantly enhance a company’s competitive edge.

- Increased Efficiency: Real-time monitoring and automation reduce manual intervention, leading to faster production cycles and lower operational costs.

- Improved Quality Control: Continuous data collection and analysis help in identifying and rectifying quality issues early in the production process.

- Enhanced Flexibility: The ability to quickly adapt to market changes and customize products to meet specific customer needs is greatly improved.

- Sustainability: Optimized resource utilization and waste reduction contribute to more sustainable manufacturing practices.

- Supply Chain Optimization: Better visibility and coordination across the supply chain ensure timely delivery of materials and finished products.

Challenges in Transitioning to a Connected Ecosystem

While the advantages are clear, transitioning to a connected and continuous manufacturing ecosystem is not without its challenges.

- Technological Integration: Upgrading legacy systems and ensuring interoperability between different technologies can be complex and costly.

- Data Security: The increased connectivity exposes manufacturers to cyber threats, necessitating robust security measures.

- Workforce Adaptation: Employees must be trained to work alongside advanced technologies and interpret complex data streams.

- Regulatory Compliance: Manufacturers must navigate a web of regulations that may not have kept pace with technological advancements.

- Initial Investment: The upfront costs of implementing a connected and continuous ecosystem can be significant, though the long-term ROI is promising.

Strategies for a Successful Transition

To overcome these challenges and reap the benefits of a connected and continuous manufacturing ecosystem, companies should consider the following strategies:

- Phased Implementation: Gradually integrating new technologies can help manage costs and minimize disruption.

- Partnerships and Collaboration: Working with technology providers and industry partners can provide access to expertise and shared resources.

- Employee Engagement: Involving employees in the transition process and providing necessary training can facilitate a smoother changeover.

- Focus on Data Management: Implementing strong data governance practices ensures the quality and security of information.

- Continuous Improvement: Adopting a mindset of ongoing innovation helps companies stay ahead of the curve.

Conclusion: Embracing the Future of Manufacturing

The transition to a connected and continuous manufacturing ecosystem is not just a trend but a necessary evolution for companies looking to thrive in a rapidly changing market. By embracing this shift, manufacturers can achieve unprecedented levels of efficiency, quality, and flexibility. While the journey may be challenging, the potential rewards make it a worthwhile endeavor for any forward-thinking business.

ETprotein: Your Partner in Nutritional Excellence

In line with the advancements in manufacturing, ETprotein company’s protein products stand as a testament to the power of innovation in the food and supplement industry. Their high-quality organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) are produced with cutting-edge technology, ensuring purity and efficacy. Whether you’re in the nutraceutical, pharmaceutical, or food and beverage industry, ETprotein’s products can help you meet the growing demand for sustainable and health-conscious options.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.