Turning Broken Rice into High-Value Rice Protein through Enzymatic Hydrolysis

Explore the efficient scale-up of enzymatic hydrolysis for transforming broken rice into high-value starch sugars and peptides for industrial application.

Keywords: broken rice,starch sugar,bioactive peptide,rice peptide,rice protein,liver

protection

Scale-up experiments play a crucial role in the field of biochemical engineering, allowing researchers to apply laboratory-scale findings to industrial-scale production. This process is essential for predicting the quality and characteristics of the final product under large-scale manufacturing conditions. It is imperative that the products maintain their desired traits throughout the scaling process, from lab-scale to full-scale production.

Enzymatic Hydrolysis of Broken Rice for Starch Sugar Production

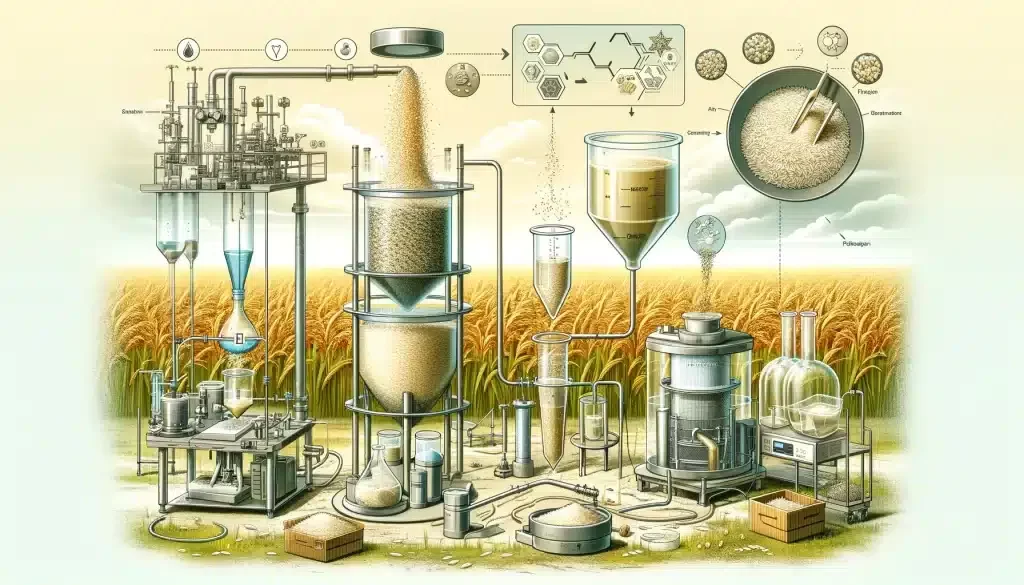

This study builds upon preliminary small-scale enzymatic hydrolysis optimization experiments, aiming to scale up the conditions to establish a viable production route. Broken rice was used as the raw material, employing enzymatic and microfiltration biotechnologies to produce starch sugars with DE values of 26-28 and 37-40, as well as rice protein and peptides. The yield of these products was measured to maximize economic benefits.

Methodology

DE Value 26-28 Starch Sugar Scale-Up:

The optimal conditions from single-factor and orthogonal optimization were scaled up in a 100 L hydrolysis tank. About 4 kg of broken rice was milled with 80 L of water in a colloid mill, and the slurry was then transferred to the hydrolysis tank. The slurry was adjusted to pH 6.3, and upon reaching a temperature of 75°C, 0.5‰ of a high-temperature-resistant amylase, Suhong AA Plus 2X, was added. The hydrolysis was conducted for 40, 50, and 60 minutes, followed by a heating step to 100°C for 10 minutes to deactivate the enzyme. The product was then filtered and concentrated, with the DE value measured afterward.

DE Value 37-40 Starch Sugar Scale-Up:

The concentrate from the first hydrolysis step was diluted to 40 L and subjected to a second round of enzymatic hydrolysis under optimized conditions. The pH was adjusted to 4.3, and at 65°C, 0.25‰ of glucoamylase, Suhong® GA III 2X, was added for 30, 40, and 50 minutes of hydrolysis. The process followed similar deactivation and filtration steps as the first round.

Rice Protein Hydrolysis for Rice Peptide Production:

The retentate from the second hydrolysis step was treated with an alkaline protease to produce rice peptides on a larger scale. The pH was adjusted to 9.0, and at 60°C, 0.25% of the enzyme was added for hydrolysis over 5, 6, and 7 hours.

Results and Discussion

The scale-up results for producing starch sugars with DE values of 26-28 and 37-40 revealed that the scaled-up conditions generally yielded lower DE values compared to lab-scale experiments. This discrepancy could be attributed to the reduced efficiency of mixing and mass transfer in larger-scale operations. Additionally, the enzymatic reactions and stirring mechanisms had a significant impact on the outcome. The study also highlighted the technical feasibility of producing starch sugars and rice peptides from broken rice on an industrial scale, with considerations for improving the enzymatic hydrolysis process and filtration methods to enhance yield and product quality.

Conclusion

This research underlines the importance of scale-up experiments in the development of efficient and economically viable production processes for biochemical products. Through careful optimization of enzymatic hydrolysis and microfiltration techniques, the study demonstrates the feasibility of converting broken rice into valuable starch sugars and peptides, laying the groundwork for future industrial applications. Further investigations are needed to refine the extraction and purification processes for rice protein and to explore the physicochemical and functional properties of the resulting products.

For more further detailed information of this research, feel free to contact our team for asssistance.

Original authors: Li Yinghui, Yuan Wenpeng (Qilu University of Technology, Jinan, 250353)

About ETprotein:

ETprotein, a reputable rice protein Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan protein and plant proteins. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, pumpkin seed protein, sunflower seed protein, mung bean protein, etc. Our offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, cater to a diverse range of industries. We serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

Our specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Our extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample our products, please contact us and email sales(at)ETprotein.com today.