Ways For Large Bakeries To Enhance Their Production Line

-

Table of Contents

- Enhancing Production Line Efficiency in Large Bakeries

- Investing in Advanced Baking Equipment

- Implementing Lean Manufacturing Principles

- Optimizing Supply Chain Management

- Adopting Automation and Robotics

- Training and Empowering Employees

- Implementing Quality Control Systems

- Utilizing Data Analytics

- Conclusion

- Enhance Your Bakery Products with ETprotein’s High-Quality Ingredients

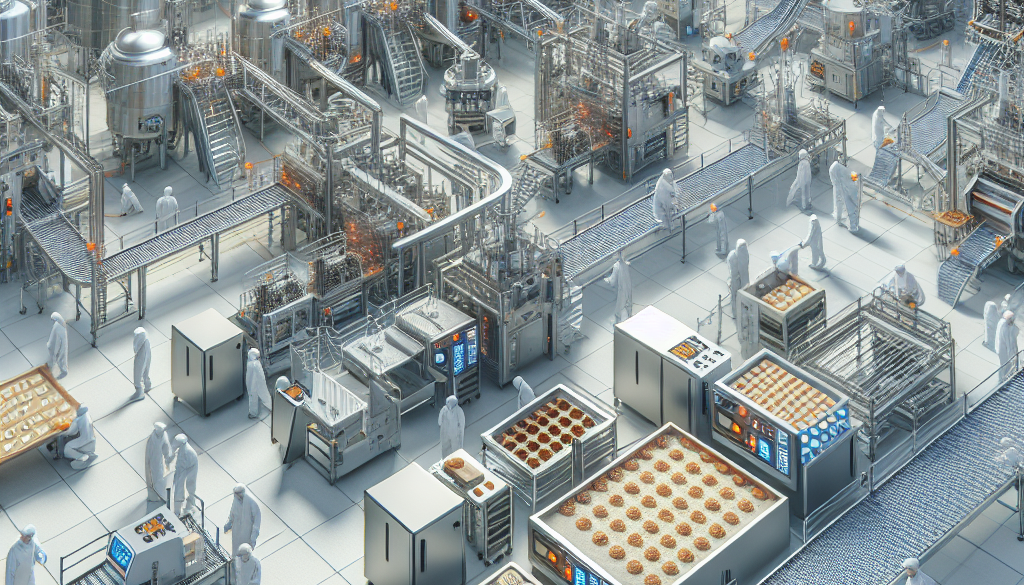

Enhancing Production Line Efficiency in Large Bakeries

The bakery industry is a dynamic and competitive sector where efficiency and productivity are crucial for success. Large bakeries, in particular, face the challenge of maintaining high-quality standards while also meeting the demands of large-scale production. Enhancing the production line is essential for these businesses to stay ahead of the competition, reduce waste, and increase profitability. In this article, we will explore various ways large bakeries can improve their production lines.

Investing in Advanced Baking Equipment

One of the primary ways to enhance a bakery’s production line is by investing in advanced baking equipment. Modern machinery can significantly increase production speed and consistency. For instance, automated dough mixers and dividers can process large batches of dough with precision, while conveyor ovens provide even baking and faster cooking times. According to a report by Grand View Research, the global bakery processing equipment market size was valued at USD 11.4 billion in 2019 and is expected to grow, indicating a trend towards automation in the industry.

Implementing Lean Manufacturing Principles

Lean manufacturing is a systematic method for waste minimization within a manufacturing system without sacrificing productivity. Large bakeries can benefit from implementing lean principles such as:

- Value stream mapping to identify and eliminate non-value-adding activities.

- 5S methodology for organizing the workplace efficiently.

- Kaizen, or continuous improvement, to encourage small, incremental changes that add up over time.

By adopting lean manufacturing, bakeries can streamline their operations, reduce costs, and improve product quality.

Optimizing Supply Chain Management

Efficient supply chain management is crucial for large bakeries to ensure the timely delivery of raw materials and the distribution of finished products. This involves:

- Building strong relationships with suppliers to secure the best prices and ensure the quality of ingredients.

- Implementing inventory management systems to track stock levels and reduce waste.

- Utilizing logistics software to optimize delivery routes and schedules.

By optimizing their supply chain, bakeries can reduce delays, minimize holding costs, and respond more quickly to market demands.

Adopting Automation and Robotics

Automation and robotics are transforming the bakery industry by performing repetitive tasks with high precision and at a faster pace than human workers. This includes:

- Automated packaging lines that can quickly seal and label products.

- Robotic arms for tasks like decorating cakes or arranging baked goods on trays.

- Automated quality control systems that use cameras and sensors to detect defects.

By incorporating automation, bakeries can increase their output while maintaining consistent product quality.

Training and Empowering Employees

While technology plays a significant role in production line enhancement, the importance of skilled employees cannot be overstated. Bakeries should invest in:

- Regular training programs to keep staff updated on the latest equipment and techniques.

- Empowerment initiatives that encourage employees to contribute ideas for improving processes.

- Cross-training to create a more flexible and responsive workforce.

Well-trained and empowered employees are more productive and can significantly contribute to the efficiency of the production line.

Implementing Quality Control Systems

Quality control is vital in the food industry. Large bakeries should implement comprehensive quality control systems that include:

- Regular inspections at different stages of the production process.

- Sampling and testing products to ensure they meet safety and quality standards.

- Traceability systems to track products from raw materials to finished goods.

These systems help to prevent recalls, protect brand reputation, and ensure customer satisfaction.

Utilizing Data Analytics

Data analytics can provide valuable insights into the production process, helping bakeries to make informed decisions. By analyzing data from various sources, bakeries can:

- Identify bottlenecks and areas for improvement in the production line.

- Forecast demand more accurately and adjust production schedules accordingly.

- Monitor equipment performance and predict maintenance needs.

With data analytics, bakeries can optimize their operations and reduce downtime.

Conclusion

Large bakeries looking to enhance their production lines have a variety of strategies at their disposal. From investing in advanced equipment and adopting lean manufacturing principles to optimizing supply chain management and implementing quality control systems, these measures can lead to significant improvements in efficiency and productivity. Additionally, the integration of automation, employee training, and data analytics can further refine production processes and contribute to the success of a large bakery.

For bakeries seeking to incorporate high-quality ingredients into their products, ETprotein offers a range of organic bulk vegan proteins and L-(+)-Ergothioneine. These ingredients can help bakeries cater to health-conscious consumers and expand their product offerings.

Enhance Your Bakery Products with ETprotein’s High-Quality Ingredients

ETprotein’s protein products are ideal for bakeries looking to innovate and improve the nutritional profile of their baked goods. With a focus on non-GMO, allergen-free ingredients, and a commitment to quality, ETprotein can help your bakery stand out in a crowded market. To learn more about their products and how they can benefit your production line, contact ETprotein today.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.