What Are Some Ways Automation Can Improve Food Processing?

-

Table of Contents

- Automation Enhancements in Food Processing: Efficiency and Safety

- Increased Efficiency and Productivity

- Enhanced Food Safety and Quality Control

- Cost Reduction and Energy Savings

- Scalability and Flexibility

- Improved Worker Safety

- Conclusion: The Future of Food Processing is Automated

- Explore ETprotein’s High-Quality Protein Products

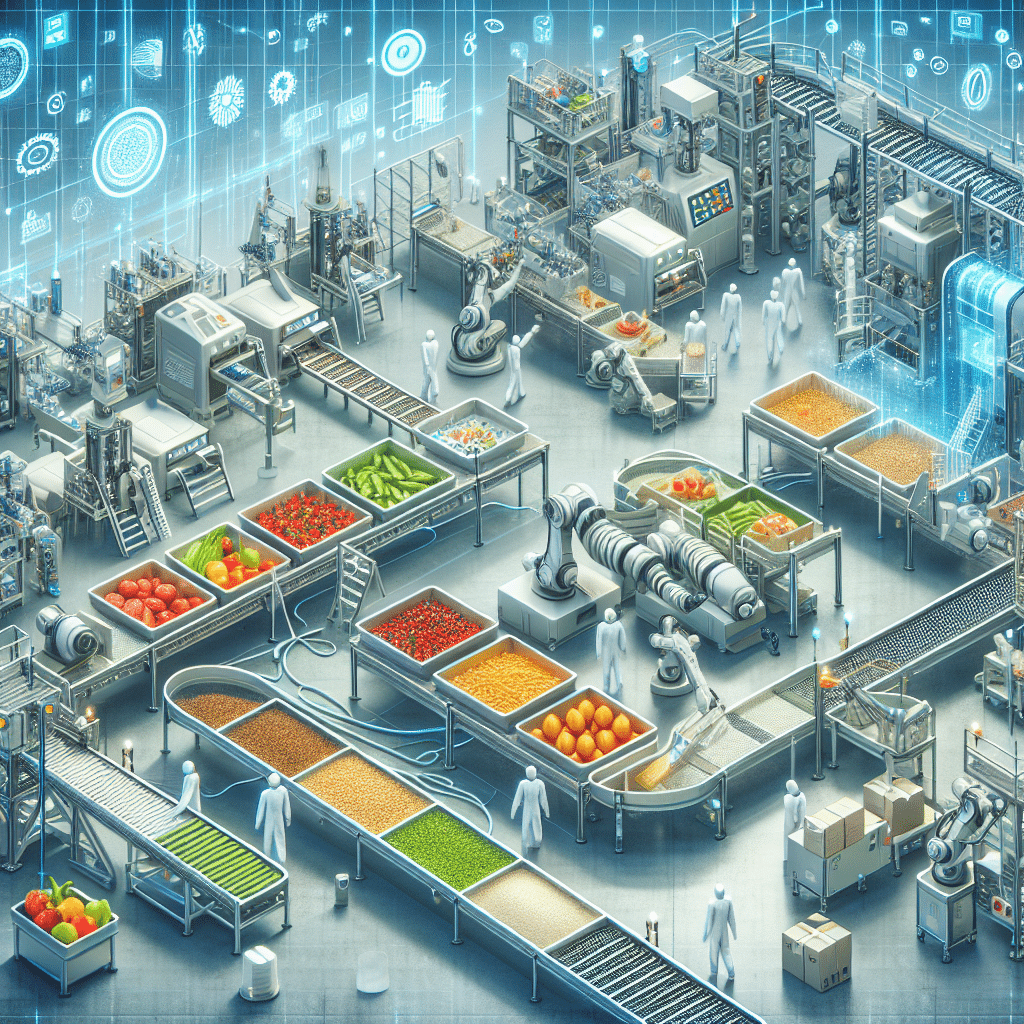

Automation Enhancements in Food Processing: Efficiency and Safety

The food processing industry is a critical component of the global economy, providing consumers with a wide array of products that are safe, nutritious, and convenient. As the demand for food continues to grow alongside the world’s population, the industry is turning to automation to improve efficiency, safety, and quality. Automation in food processing not only streamlines operations but also helps in meeting the stringent regulatory standards and consumer expectations. In this article, we will explore the various ways in which automation can revolutionize the food processing sector.

Increased Efficiency and Productivity

One of the primary benefits of automation in food processing is the significant increase in efficiency and productivity. Automated systems can operate continuously without the need for breaks, leading to higher output rates. Here are some ways automation achieves this:

- Consistent Production Speeds: Automated machinery can maintain consistent production speeds, ensuring a steady flow of products from the production line.

- Reduction in Human Error: Machines programmed to perform specific tasks reduce the likelihood of human error, which can lead to product waste and downtime.

- Optimized Resource Management: Automation allows for precise control over ingredients and resources, minimizing waste and reducing costs.

Enhanced Food Safety and Quality Control

Food safety is paramount in the processing industry. Automation can significantly reduce the risk of contamination and ensure consistent product quality. Here’s how:

- Minimized Human Contact: By reducing the need for human handling, automated systems lower the risk of contamination from pathogens or foreign objects.

- Advanced Monitoring and Tracking: Automated sensors and cameras can monitor food quality and safety parameters, quickly identifying and addressing any deviations.

- Traceability: Automation facilitates better traceability throughout the supply chain, making it easier to track the source of ingredients and manage recalls if necessary.

Cost Reduction and Energy Savings

Automation can lead to significant cost savings in the long run. Automated equipment often requires less energy to operate and can be optimized for peak efficiency. Cost reductions are realized through:

- Labor Cost Savings: Although the initial investment in automation may be high, the reduction in labor costs over time can be substantial.

- Energy-Efficient Operations: Automated systems can be designed to consume less energy, contributing to lower operational costs and a smaller carbon footprint.

- Maintenance Predictability: Predictive maintenance enabled by automation can prevent costly breakdowns and unplanned downtime.

Scalability and Flexibility

Automation provides food processors with the ability to scale operations up or down quickly in response to market demands. Automated systems can be reprogrammed and adapted to new tasks, offering:

- Quick Adaptation to Market Changes: Automation allows for rapid changes in production to accommodate new products or packaging designs.

- Modular Systems: Many automated systems are modular, meaning they can be expanded or reconfigured as the business grows or needs change.

Improved Worker Safety

Automation also enhances worker safety by taking over dangerous or repetitive tasks that could lead to injury. This includes:

- Reduction in Manual Labor: Heavy lifting and repetitive motions can be offloaded to machines, reducing the risk of workplace injuries.

- Isolation from Hazardous Environments: Automated systems can operate in extreme temperatures or handle hazardous materials, protecting workers from harmful conditions.

Conclusion: The Future of Food Processing is Automated

In conclusion, automation presents a multitude of benefits for the food processing industry. From enhancing efficiency and productivity to improving food safety and quality control, the advantages are clear. Additionally, cost reductions, energy savings, scalability, flexibility, and improved worker safety are compelling reasons for food processors to embrace automation. As technology continues to advance, we can expect even more innovative solutions to emerge, further transforming the industry.

For those in the food processing industry looking to incorporate high-quality protein into their products, ETprotein offers a range of organic bulk vegan proteins and L-(+)-Ergothioneine (EGT) that meet the highest standards. Their products are non-GMO, allergen-free, and come with a guarantee of purity over 98%, making them an excellent choice for businesses aiming to improve their offerings with the help of automation.

Explore ETprotein’s High-Quality Protein Products

ETprotein is a trusted manufacturer and supplier of premium protein products that can enhance the nutritional profile of food and beverage items. Their extensive range of proteins, including organic rice protein, pea protein, and various seed proteins, are ideal for businesses looking to innovate and improve their product lines. With a commitment to quality and customer satisfaction, ETprotein is the go-to source for all your protein needs.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.