What Can Food and Beverage Companies do to Maintain Safety?

-

Table of Contents

- Ensuring Safety in Food and Beverage Production: Best Practices for Companies

- Understanding the Importance of Food Safety

- Implementing Robust Hazard Analysis and Critical Control Points (HACCP) Systems

- Adhering to Good Manufacturing Practices (GMP)

- Investing in Employee Training and Education

- Utilizing Advanced Technology for Food Safety

- Regular Safety Audits and Certifications

- Engaging with Suppliers and Partners

- Responding Effectively to Food Safety Incidents

- Conclusion: Commitment to Continuous Improvement

- ETprotein: Your Partner in Quality Protein Products

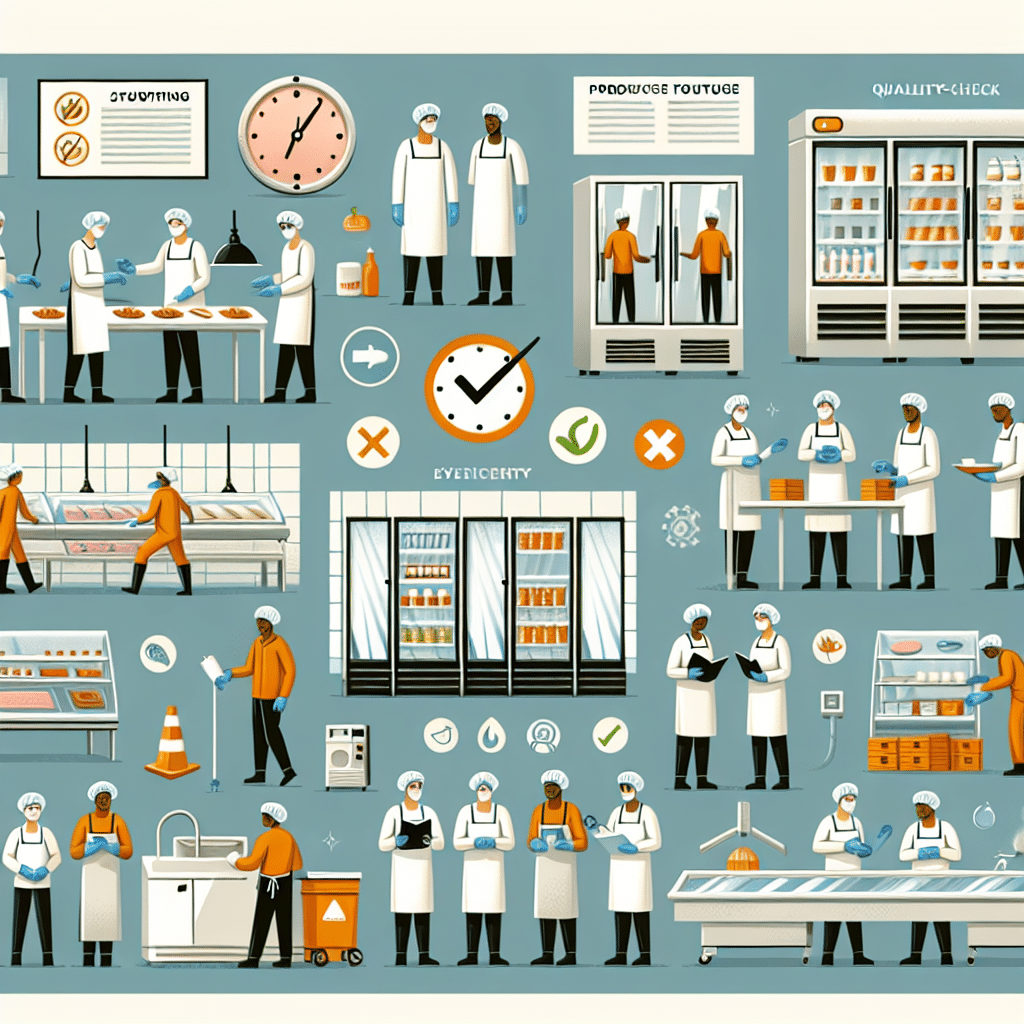

Ensuring Safety in Food and Beverage Production: Best Practices for Companies

The food and beverage industry is a cornerstone of the global economy, with millions of products consumed daily. Ensuring the safety of these products is paramount, as the consequences of unsafe food can be severe, ranging from public health crises to significant financial losses for companies. In this article, we will explore the various strategies and practices that food and beverage companies can implement to maintain the highest safety standards.

Understanding the Importance of Food Safety

Food safety is a critical concern for consumers and regulators alike. According to the World Health Organization (WHO), an estimated 600 million – almost 1 in 10 people in the world – fall ill after eating contaminated food, and 420,000 die every year. These statistics underscore the need for stringent safety measures in the food and beverage industry.

Implementing Robust Hazard Analysis and Critical Control Points (HACCP) Systems

One of the most effective ways to ensure food safety is through the implementation of HACCP systems. This preventive approach to food safety identifies physical, chemical, and biological hazards in production processes that can cause the finished product to be unsafe and designs measurements to reduce these risks to a safe level.

- Conduct a hazard analysis to identify potential hazards that could occur in the food production process.

- Determine the critical control points (CCPs) where controls are essential to prevent or eliminate a food safety hazard.

- Establish critical limits for each CCP.

- Implement monitoring procedures to ensure each CCP stays within its critical limits.

- Establish corrective actions if monitoring indicates that a CCP is not within the established limits.

- Implement record-keeping procedures to document the HACCP system.

- Regularly verify that the HACCP system is working effectively.

Adhering to Good Manufacturing Practices (GMP)

Good Manufacturing Practices are guidelines that provide a system of processes, procedures, and documentation to assure that the product has the identity, strength, composition, quality, and purity that it is represented to possess. Key components of GMP include:

- Ensuring the cleanliness of facilities and equipment.

- Maintaining proper personal hygiene for all employees.

- Controlling environmental conditions to prevent cross-contamination.

- Conducting regular inspections and equipment maintenance.

- Properly training staff on safety protocols.

Investing in Employee Training and Education

Human error can be a significant source of food safety issues. Therefore, investing in comprehensive training programs for employees is crucial. These programs should cover:

- Food handling and preparation practices.

- Personal hygiene and health requirements.

- Cleaning and sanitation procedures.

- Emergency procedures for handling food safety incidents.

Utilizing Advanced Technology for Food Safety

Technology plays a pivotal role in modern food safety management. Innovations such as blockchain for traceability, sensors for real-time monitoring of storage conditions, and AI for predicting potential contamination events are becoming increasingly prevalent. These technologies can help companies:

- Track the movement of ingredients and products through the supply chain.

- Monitor temperature and humidity in storage and transportation.

- Analyze data to predict and prevent potential safety issues.

Regular Safety Audits and Certifications

Regular audits and certifications from third-party organizations can help ensure that food safety practices meet or exceed industry standards. Certifications such as ISO 22000, Global Food Safety Initiative (GFSI), and Safe Quality Food (SQF) are recognized indicators of a company’s commitment to food safety.

Engaging with Suppliers and Partners

The safety of food products is not solely dependent on the practices within a single company but also on the actions of suppliers and partners. Companies must:

- Conduct thorough vetting of suppliers and their safety practices.

- Establish clear safety expectations and requirements for all partners.

- Regularly review and audit partner facilities and processes.

Responding Effectively to Food Safety Incidents

Despite the best efforts, food safety incidents can still occur. An effective response plan should include:

- Immediate action to contain and address the source of the problem.

- Transparent communication with consumers, regulators, and other stakeholders.

- A thorough investigation to prevent future incidents.

Conclusion: Commitment to Continuous Improvement

Maintaining safety in the food and beverage industry requires a multifaceted approach that includes robust safety systems, employee training, technological advancements, regular audits, and strong supplier relationships. By continuously improving these areas, companies can ensure the safety of their products and the well-being of their consumers.

ETprotein: Your Partner in Quality Protein Products

In line with maintaining high safety standards, ETprotein offers a range of protein products that meet the rigorous demands of the food and beverage industry. Their organic bulk vegan proteins and L-(+)-Ergothioneine are produced with a commitment to quality, safety, and sustainability. Whether you’re looking for ingredients for sports nutrition, weight management, dietary supplements, or infant formula, ETprotein has the expertise and products to support your needs.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.