What Role Can Robotics Play In Bakery Production?

-

Table of Contents

- Robotics in Bakery Production: Enhancing Efficiency and Quality

- The Rise of Robotics in Bakery Production

- Key Areas Where Robotics Make an Impact

- Statistics Supporting the Adoption of Robotics

- Robotics in Action: Real-World Applications

- Challenges and Considerations

- Conclusion: Embracing the Future of Bakery Production

- ETprotein: Elevating Bakery Products with High-Quality Proteins

Robotics in Bakery Production: Enhancing Efficiency and Quality

The bakery industry has always been a blend of traditional craftsmanship and innovation. As consumer demand for baked goods continues to rise, bakeries are turning to technology to increase production, maintain consistency, and improve efficiency. Robotics, in particular, has emerged as a game-changer in the world of bakery production. This article explores the multifaceted role that robotics can play in transforming bakery operations.

The Rise of Robotics in Bakery Production

Robotics technology has advanced significantly over the past few decades, becoming more accessible and adaptable to various industries, including food production. In the bakery sector, the integration of robotics has been driven by the need to meet high-volume demands while maintaining product quality and safety standards.

Key Areas Where Robotics Make an Impact

- Consistency and Precision: Robotics ensures uniformity in product size, shape, and weight, which is crucial for customer satisfaction and brand reputation.

- Efficiency and Speed: Automated systems can operate at a pace that far exceeds human capabilities, leading to increased throughput and faster time-to-market.

- Labor Shortages: Robotics can fill gaps in the workforce, especially in repetitive and physically demanding tasks, reducing the strain on human workers.

- Food Safety: By minimizing human contact with the products, robotics can help reduce the risk of contamination and improve overall food safety.

- Customization: Advanced robotics can be programmed to produce customized baked goods, catering to the growing market for personalized products.

Statistics Supporting the Adoption of Robotics

According to a report by the Association for Advancing Automation, the food and consumer goods industries saw a 56% increase in robotics orders in the first quarter of 2021 compared to the previous year. This surge reflects the growing recognition of the benefits that robotics can bring to production lines, including bakeries.

Robotics in Action: Real-World Applications

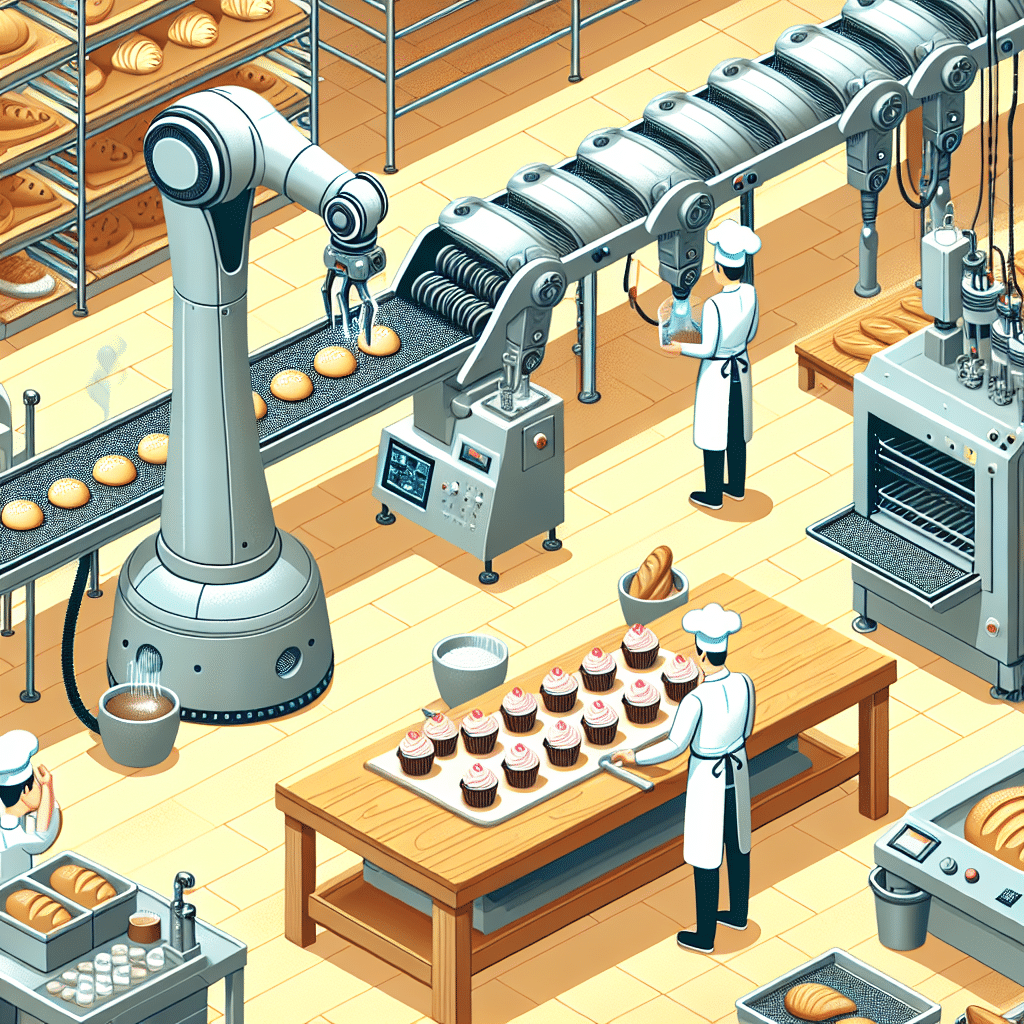

Robotics in bakery production is not a futuristic concept—it’s already in action. Here are some areas where robotics is making a significant impact:

- Dough Preparation: Robots can mix ingredients with precision, ensuring consistency in dough texture and quality.

- Shaping and Molding: Automated systems can shape dough into various forms, from bread loaves to intricate pastry designs.

- Decorating and Icing: With delicate movements, robots can decorate cakes and pastries, replicating the work of skilled artisans.

- Packaging: Robotics can streamline the packaging process, from sorting and wrapping products to boxing them for distribution.

- Palletizing: Heavy lifting tasks, such as stacking boxes onto pallets, can be performed effortlessly by robotic arms.

Challenges and Considerations

While the benefits of robotics in bakery production are clear, there are challenges to consider:

- Initial Investment: The cost of implementing robotic systems can be high, though the long-term savings often justify the investment.

- Technical Expertise: Operating and maintaining robotic equipment requires specialized skills, which may necessitate additional training for staff.

- Integration with Existing Systems: Integrating new robotics with current production lines can be complex and requires careful planning.

Conclusion: Embracing the Future of Bakery Production

The role of robotics in bakery production is multifaceted and growing. By enhancing efficiency, ensuring product consistency, and addressing labor challenges, robotics is poised to revolutionize the way bakeries operate. As technology continues to evolve, we can expect even more innovative applications of robotics in the bakery industry, leading to smarter, safer, and more sustainable production processes.

ETprotein: Elevating Bakery Products with High-Quality Proteins

As bakeries embrace robotics for production, the demand for high-quality ingredients remains paramount. ETprotein offers a range of organic bulk vegan proteins that can enhance the nutritional profile of baked goods. Their non-GMO, allergen-free proteins, including rice, pea, and seed-based options, are ideal for creating healthier bakery products that cater to diverse dietary needs.

With the precision of robotics in production and the quality of ETprotein’s offerings, bakeries can deliver products that are not only efficiently produced but also nutritionally superior. To explore how ETprotein’s proteins can be integrated into your bakery’s product line, contact them at sales(at)ETprotein.com.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.