Why Safety is an Important Component in the Meat Processing Industry

-

Table of Contents

- Meat Processing Safety: A Critical Industry Focus

- The High Stakes of Meat Processing Safety

- Worker Safety and Health

- Consumer Health and Safety

- Business Continuity and Reputation

- Statistics Highlighting the Importance of Safety

- Implementing Safety Measures in Meat Processing

- Worker Training and Protective Equipment

- Sanitation and Hygiene Protocols

- Equipment Maintenance and Safety Features

- Quality Control and Traceability

- Conclusion: The Non-Negotiable Priority of Safety

- Discover ETprotein’s High-Quality Protein Products

Meat Processing Safety: A Critical Industry Focus

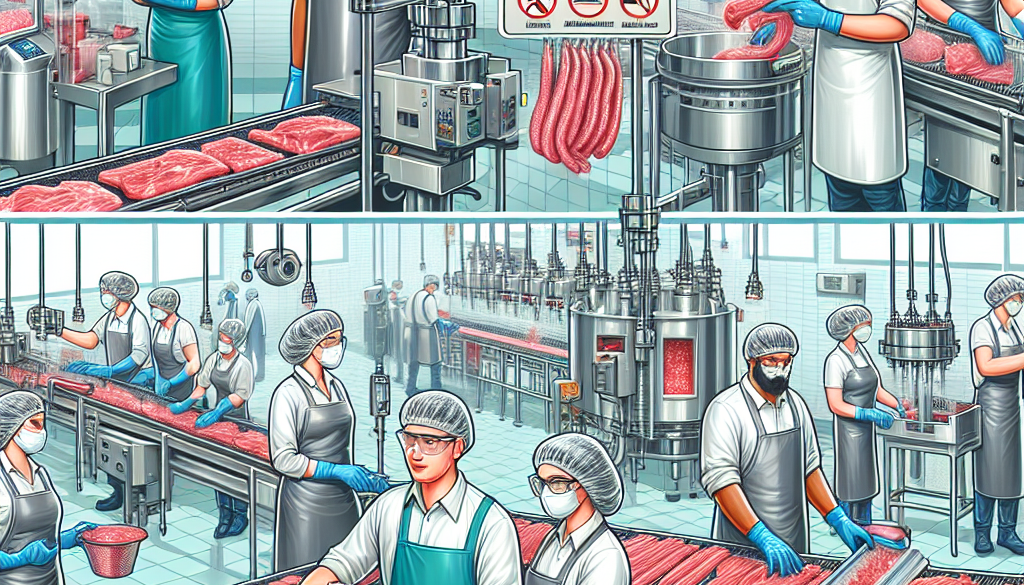

The meat processing industry is a vital component of the global food supply chain, providing essential protein to millions of people daily. However, the process of turning livestock into consumable products is fraught with potential hazards. Ensuring safety in meat processing is not just a moral and legal obligation but also a critical business imperative. This article delves into the reasons why safety is an indispensable aspect of the meat processing industry, supported by statistics and expert insights.

The High Stakes of Meat Processing Safety

Meat processing involves various stages, from slaughtering and cutting to packaging and distribution. Each step presents unique risks that can lead to severe consequences if not managed properly. The importance of safety in this industry cannot be overstated, as it impacts workers, consumers, and businesses alike.

Worker Safety and Health

- Occupational Hazards: Meat processing plants are known for their challenging work conditions. Workers are exposed to sharp tools, heavy machinery, and repetitive motions, leading to a high risk of injuries and musculoskeletal disorders.

- Chemical and Biological Exposure: Employees may also face exposure to harmful chemicals used in cleaning and processing, as well as biological hazards such as bacteria and viruses present in raw meat.

- Regulatory Compliance: Adhering to safety regulations is not optional. Regulatory bodies like OSHA in the United States enforce strict guidelines to protect workers, and non-compliance can result in hefty fines and legal repercussions.

Consumer Health and Safety

- Foodborne Illness Prevention: The meat processing industry must prevent contamination of meat products with pathogens like E. coli, Salmonella, and Listeria, which can cause serious illness or even death among consumers.

- Product Recalls: Safety lapses can lead to costly product recalls, damaging consumer trust and brand reputation, and incurring significant financial losses.

Business Continuity and Reputation

- Financial Impact: Safety incidents can result in operational downtime, legal costs, and increased insurance premiums, affecting a company’s bottom line.

- Brand Image: A strong safety record enhances a company’s reputation, while safety failures can tarnish a brand for years.

Statistics Highlighting the Importance of Safety

Recent data underscores the critical need for safety in the meat processing industry:

- According to the U.S. Bureau of Labor Statistics, the incidence rate of nonfatal occupational injuries and illnesses in animal slaughtering and processing was higher than the average for all industries in 2019.

- The Centers for Disease Control and Prevention (CDC) reports that foodborne pathogens cause approximately 48 million illnesses, 128,000 hospitalizations, and 3,000 deaths in the United States each year.

- The USDA’s Food Safety and Inspection Service (FSIS) issued recalls for over 20 million pounds of meat and poultry products due to safety concerns in 2020 alone.

Implementing Safety Measures in Meat Processing

Given the high stakes, it is imperative for meat processing facilities to implement comprehensive safety measures:

Worker Training and Protective Equipment

Regular training on proper handling techniques and the use of personal protective equipment (PPE) can significantly reduce the risk of injuries and exposure to hazards.

Sanitation and Hygiene Protocols

Maintaining a clean and sanitary environment is essential to prevent the spread of pathogens. This includes regular cleaning and disinfection of surfaces, tools, and equipment.

Equipment Maintenance and Safety Features

Regular maintenance of machinery and the integration of safety features such as guards and emergency stop buttons can prevent accidents and injuries.

Quality Control and Traceability

Implementing rigorous quality control measures and maintaining traceability of products from farm to table ensures that any safety issues can be quickly identified and addressed.

Conclusion: The Non-Negotiable Priority of Safety

In conclusion, safety in the meat processing industry is a non-negotiable priority that safeguards workers, protects consumers, and secures the integrity of businesses. By investing in safety measures, training, and compliance with regulations, the industry can mitigate risks and uphold its responsibility to provide safe, high-quality products to the market.

Discover ETprotein’s High-Quality Protein Products

In line with the commitment to safety and quality in the food industry, ETprotein offers a range of superior protein products that meet the highest standards. Their organic bulk vegan proteins and L-(+)-Ergothioneine are produced with a focus on safety, purity, and sustainability, making them an excellent choice for businesses looking to enhance their offerings with safe and reliable ingredients.

About ETprotein:

ETprotein, a reputable protein and L-(+)-Ergothioneine (EGT) Chinese factory manufacturer and supplier, is renowned for producing, stocking, exporting, and delivering the highest quality organic bulk vegan proteins and L-(+)-Ergothioneine. They include Organic rice protein, clear rice protein, pea protein, clear pea protein, watermelon seed protein, pumpkin seed protein, sunflower seed protein, mung bean protein, peanut protein, and L-(+)-Ergothioneine EGT Pharmaceutical grade, L-(+)-Ergothioneine EGT food grade, L-(+)-Ergothioneine EGT cosmetic grade, L-(+)-Ergothioneine EGT reference grade and L-(+)-Ergothioneine EGT standard. Their offerings, characterized by a neutral taste, non-GMO, allergen-free attributes, with L-(+)-Ergothioneine purity over 98%, 99%, cater to a diverse range of industries. They serve nutraceutical, pharmaceutical, cosmeceutical, veterinary, as well as food and beverage finished product distributors, traders, and manufacturers across Europe, USA, Canada, Australia, Thailand, Japan, Korea, Brazil, and Chile, among others.

ETprotein specialization includes exporting and delivering tailor-made protein powder and finished nutritional supplements. Their extensive product range covers sectors like Food and Beverage, Sports Nutrition, Weight Management, Dietary Supplements, Health and Wellness Products, and Infant Formula, ensuring comprehensive solutions to meet all your protein needs.

As a trusted company by leading global food and beverage brands and Fortune 500 companies, ETprotein reinforces China’s reputation in the global arena. For more information or to sample their products, please contact them and email sales(at)ETprotein.com today.